Aluminium Design and Construction John Dwight

Aluminium Design and Construction John Dwight

Aluminium Design and Construction John Dwight

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

The problem is to decide on a suitable value of the parameter s for<br />

such welds. An instinctive procedure might be to consider a section<br />

transverse to the axis of the weld, <strong>and</strong> determine s in the same way as<br />

for a long straight joint of the same geometry, using the data in Table<br />

6.2. This is not acceptable. In practice, the whole of an attachment<br />

weld, or all of one pass, will be laid non-stop without pause. The resulting<br />

heat flow, which is complex, would have to be determined on a one-off<br />

basis using a specialist computer program or else experimentally, neither<br />

of which may be practicable. The only sure thing is that the heat flow,<br />

<strong>and</strong> hence the pattern of softening, will be more unfavourable than that<br />

based on a straight weld.<br />

The designer, therefore, should first calculate the value of s for an<br />

equivalent long straight weld of the same size, <strong>and</strong> then increase this<br />

by a suitable factor to allow for all the imponderables. For lack of hard<br />

data, we would suggest an arbitrary increase of 25% in the value of s,<br />

although this may be pessimistic when applied to a very short attachment<br />

weld (connection of a small lug, say).<br />

With a wide attachment, the precise amount that the HAZ projects<br />

at either side is relatively unimportant, since it forms only a small part<br />

of the total affected width. The penetration into the thickness is more<br />

critical. If a small attachment weld is used on a relatively thick member,<br />

the HAZ penetrates only part way into the thickness, leading to a much<br />

smaller area of HAZ than that based on full penetration such as would<br />

be predicted by the one-inch rule.<br />

6.5.10 Definition of an isolated weld (10A-rule)<br />

For an isolated single-pass weld, it is permissible to use the more favourable<br />

HAZ parameters based on strict thermal control, even when only normal<br />

control is specified. How do we define ‘isolated’? The following ‘10Arule’<br />

for so doing is derived from Rosenthal’s heat-flow equations [22].<br />

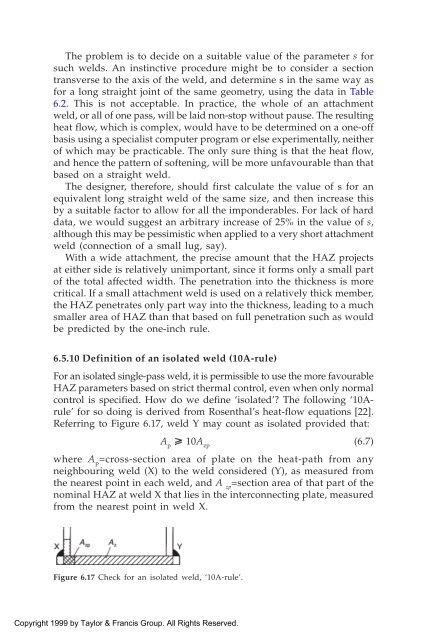

Referring to Figure 6.17, weld Y may count as isolated provided that:<br />

A p 10A zp (6.7)<br />

where A p =cross-section area of plate on the heat-path from any<br />

neighbouring weld (X) to the weld considered (Y), as measured from<br />

the nearest point in each weld, <strong>and</strong> A zp =section area of that part of the<br />

nominal HAZ at weld X that lies in the interconnecting plate, measured<br />

from the nearest point in weld X.<br />

Figure 6.17 Check for an isolated weld, ‘10A-rule’.<br />

Copyright 1999 by Taylor & Francis Group. All Rights Reserved.