THESIS - ROC CH ... - FINAL - resubmission.pdf - University of Guelph

THESIS - ROC CH ... - FINAL - resubmission.pdf - University of Guelph

THESIS - ROC CH ... - FINAL - resubmission.pdf - University of Guelph

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

a<br />

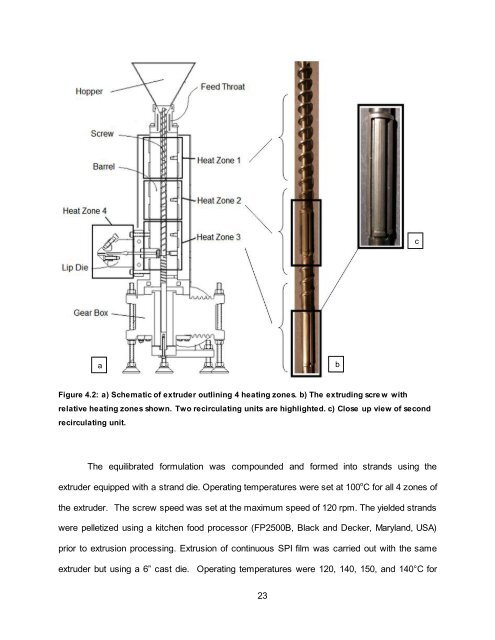

Figure 4.2: a) Schematic <strong>of</strong> extruder outlining 4 heating zones. b) The extruding scre w with<br />

relative heating zones shown. Two recirculating units are highlighted. c) Close up view <strong>of</strong> second<br />

recirculating unit.<br />

The equilibrated formulation was compounded and formed into strands using the<br />

extruder equipped with a strand die. Operating temperatures were set at 100 o C for all 4 zones <strong>of</strong><br />

the extruder. The screw speed was set at the maximum speed <strong>of</strong> 120 rpm. The yielded strands<br />

were pelletized using a kitchen food processor (FP2500B, Black and Decker, Maryland, USA)<br />

prior to extrusion processing. Extrusion <strong>of</strong> continuous SPI film was carried out with the same<br />

extruder but using a 6‖ cast die. Operating temperatures were 120, 140, 150, and 140°C for<br />

23<br />

b<br />

c