2007-08 - Aditya Birla Nuvo, Ltd

2007-08 - Aditya Birla Nuvo, Ltd

2007-08 - Aditya Birla Nuvo, Ltd

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

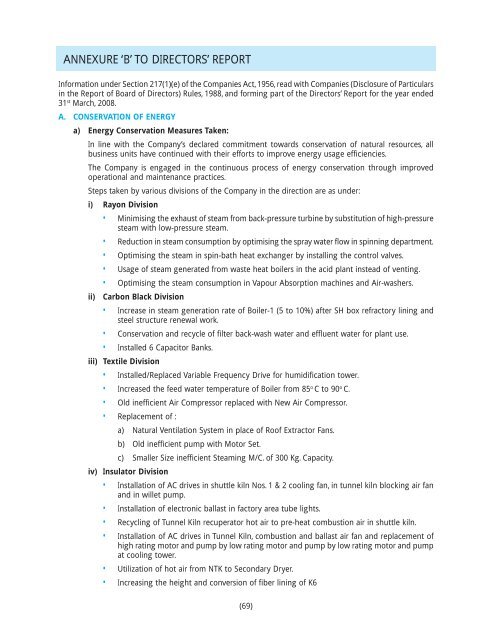

ANNEXURE ‘B’ TO DIRECTORS’ REPORTInformation under Section 217(1)(e) of the Companies Act, 1956, read with Companies (Disclosure of Particularsin the Report of Board of Directors) Rules, 1988, and forming part of the Directors’ Report for the year ended31 st March, 20<strong>08</strong>.A. CONSERVATION OF ENERGYa) Energy Conservation Measures Taken:In line with the Company’s declared commitment towards conservation of natural resources, allbusiness units have continued with their efforts to improve energy usage efficiencies.The Company is engaged in the continuous process of energy conservation through improvedoperational and maintenance practices.Steps taken by various divisions of the Company in the direction are as under:i) Rayon Division• Minimising the exhaust of steam from back-pressure turbine by substitution of high-pressuresteam with low-pressure steam.• Reduction in steam consumption by optimising the spray water flow in spinning department.• Optimising the steam in spin-bath heat exchanger by installing the control valves.• Usage of steam generated from waste heat boilers in the acid plant instead of venting.• Optimising the steam consumption in Vapour Absorption machines and Air-washers.ii) Carbon Black Division• Increase in steam generation rate of Boiler-1 (5 to 10%) after SH box refractory lining andsteel structure renewal work.• Conservation and recycle of filter back-wash water and effluent water for plant use.• Installed 6 Capacitor Banks.iii) Textile Division• Installed/Replaced Variable Frequency Drive for humidification tower.• Increased the feed water temperature of Boiler from 85 o C to 90 o C.• Old inefficient Air Compressor replaced with New Air Compressor.• Replacement of :a) Natural Ventilation System in place of Roof Extractor Fans.b) Old inefficient pump with Motor Set.c) Smaller Size inefficient Steaming M/C. of 300 Kg. Capacity.iv) Insulator Division• Installation of AC drives in shuttle kiln Nos. 1 & 2 cooling fan, in tunnel kiln blocking air fanand in willet pump.• Installation of electronic ballast in factory area tube lights.• Recycling of Tunnel Kiln recuperator hot air to pre-heat combustion air in shuttle kiln.• Installation of AC drives in Tunnel Kiln, combustion and ballast air fan and replacement ofhigh rating motor and pump by low rating motor and pump by low rating motor and pumpat cooling tower.• Utilization of hot air from NTK to Secondary Dryer.• Increasing the height and conversion of fiber lining of K6(69)