Operating instructions - EWM Hightec Welding GmbH

Operating instructions - EWM Hightec Welding GmbH

Operating instructions - EWM Hightec Welding GmbH

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

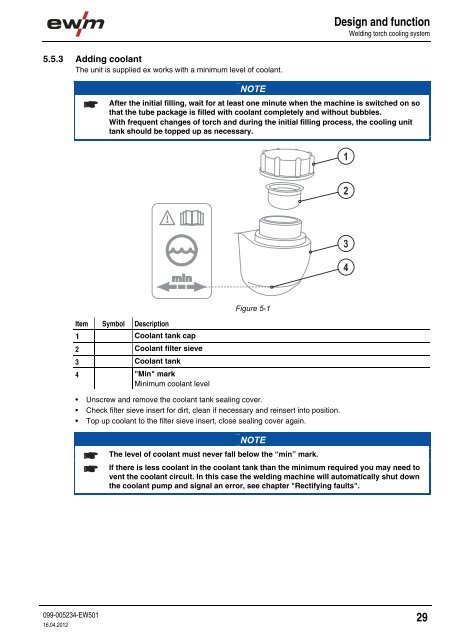

Design and function<strong>Welding</strong> torch cooling system5.5.3 Adding coolantThe unit is supplied ex works with a minimum level of coolant.NOTEAfter the initial filling, wait for at least one minute when the machine is switched on sothat the tube package is filled with coolant completely and without bubbles.With frequent changes of torch and during the initial filling process, the cooling unittank should be topped up as necessary.Item Symbol Description 01 Coolant tank cap2 Coolant filter sieve3 Coolant tank4 "Min" markMinimum coolant levelFigure 5-1• Unscrew and remove the coolant tank sealing cover.• Check filter sieve insert for dirt, clean if necessary and reinsert into position.• Top up coolant to the filter sieve insert, close sealing cover again.NOTEThe level of coolant must never fall below the “min” mark.If there is less coolant in the coolant tank than the minimum required you may need tovent the coolant circuit. In this case the welding machine will automatically shut downthe coolant pump and signal an error, see chapter "Rectifying faults".099-005234-EW50116.04.201229