Operating instructions - EWM Hightec Welding GmbH

Operating instructions - EWM Hightec Welding GmbH

Operating instructions - EWM Hightec Welding GmbH

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

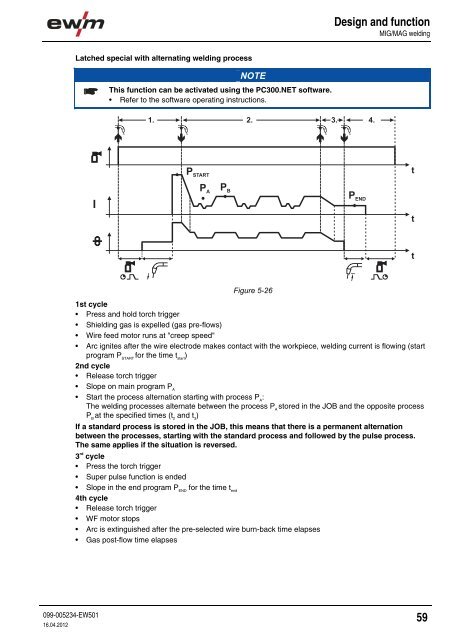

Design and functionMIG/MAG weldingLatched special with alternating welding processNOTEThis function can be activated using the PC300.NET software.• Refer to the software operating <strong>instructions</strong>.1. 2. 3. 4.IPP AP BP ENDSTARTFigure 5-26ttt1st cycle• Press and hold torch trigger• Shielding gas is expelled (gas pre-flows)• Wire feed motor runs at "creep speed"• Arc ignites after the wire electrode makes contact with the workpiece, welding current is flowing (startprogram P STARTfor the time t start)2nd cycle• Release torch trigger• Slope on main program P A• Start the process alternation starting with process P A:The welding processes alternate between the process P Astored in the JOB and the opposite processP Bat the specified times (t 2and t 3)If a standard process is stored in the JOB, this means that there is a permanent alternationbetween the processes, starting with the standard process and followed by the pulse process.The same applies if the situation is reversed.3 rd cycle• Press the torch trigger• Super pulse function is ended• Slope in the end program P ENDfor the time t end4th cycle• Release torch trigger• WF motor stops• Arc is extinguished after the pre-selected wire burn-back time elapses• Gas post-flow time elapses099-005234-EW50116.04.201259