Operating instructions - EWM Hightec Welding GmbH

Operating instructions - EWM Hightec Welding GmbH

Operating instructions - EWM Hightec Welding GmbH

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

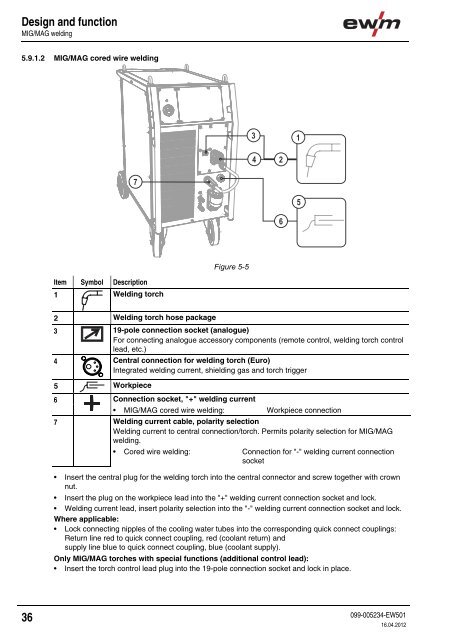

Design and functionMIG/MAG welding5.9.1.2 MIG/MAG cored wire weldingFigure 5-5Item Symbol Description 01 <strong>Welding</strong> torch2 <strong>Welding</strong> torch hose package3 19-pole connection socket (analogue)For connecting analogue accessory components (remote control, welding torch controllead, etc.)4 Central connection for welding torch (Euro)Integrated welding current, shielding gas and torch trigger5 Workpiece67Connection socket, "+" welding current• MIG/MAG cored wire welding: Workpiece connection<strong>Welding</strong> current cable, polarity selection<strong>Welding</strong> current to central connection/torch. Permits polarity selection for MIG/MAGwelding.• Cored wire welding: Connection for "-" welding current connectionsocket• Insert the central plug for the welding torch into the central connector and screw together with crownnut.• Insert the plug on the workpiece lead into the "+" welding current connection socket and lock.• <strong>Welding</strong> current lead, insert polarity selection into the "-" welding current connection socket and lock.Where applicable:• Lock connecting nipples of the cooling water tubes into the corresponding quick connect couplings:Return line red to quick connect coupling, red (coolant return) andsupply line blue to quick connect coupling, blue (coolant supply).Only MIG/MAG torches with special functions (additional control lead):• Insert the torch control lead plug into the 19-pole connection socket and lock in place.36099-005234-EW50116.04.2012