Operating instructions - EWM Hightec Welding GmbH

Operating instructions - EWM Hightec Welding GmbH

Operating instructions - EWM Hightec Welding GmbH

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

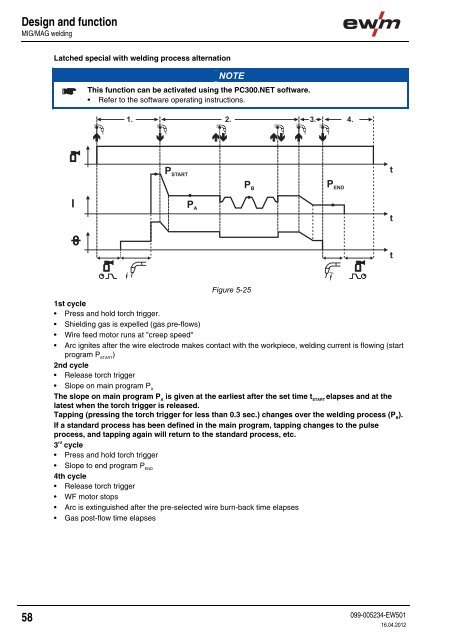

Design and functionMIG/MAG weldingLatched special with welding process alternationNOTEThis function can be activated using the PC300.NET software.• Refer to the software operating <strong>instructions</strong>.1. 2. 3. 4.IP BP ENDP STARTFigure 5-25ttt1st cycle• Press and hold torch trigger.• Shielding gas is expelled (gas pre-flows)• Wire feed motor runs at "creep speed"• Arc ignites after the wire electrode makes contact with the workpiece, welding current is flowing (startprogram P START)2nd cycle• Release torch trigger• Slope on main program P AThe slope on main program P Ais given at the earliest after the set time t STARTelapses and at thelatest when the torch trigger is released.Tapping (pressing the torch trigger for less than 0.3 sec.) changes over the welding process (P B).If a standard process has been defined in the main program, tapping changes to the pulseprocess, and tapping again will return to the standard process, etc.3 rd cycle• Press and hold torch trigger• Slope to end program P END4th cycle• Release torch trigger• WF motor stops• Arc is extinguished after the pre-selected wire burn-back time elapses• Gas post-flow time elapses58099-005234-EW50116.04.2012