Operating instructions - EWM Hightec Welding GmbH

Operating instructions - EWM Hightec Welding GmbH

Operating instructions - EWM Hightec Welding GmbH

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

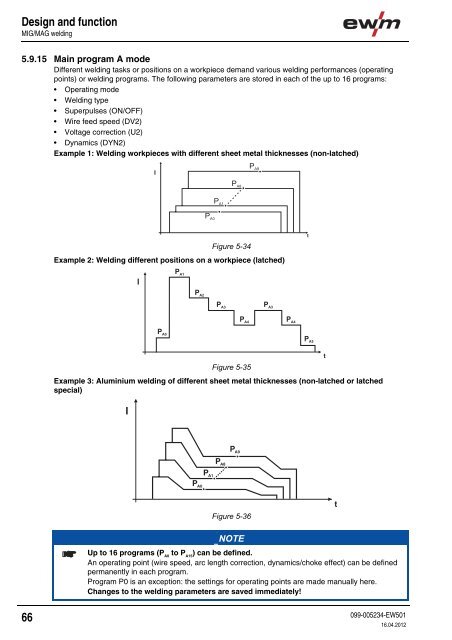

Design and functionMIG/MAG welding5.9.15 Main program A modeDifferent welding tasks or positions on a workpiece demand various welding performances (operatingpoints) or welding programs. The following parameters are stored in each of the up to 16 programs:• <strong>Operating</strong> mode• <strong>Welding</strong> type• Superpulses (ON/OFF)• Wire feed speed (DV2)• Voltage correction (U2)• Dynamics (DYN2)Example 1: <strong>Welding</strong> workpieces with different sheet metal thicknesses (non-latched)IP A0P A1P A8P A9Figure 5-34Example 2: <strong>Welding</strong> different positions on a workpiece (latched)tIP A1P A2P A3 P A3P A4P A4P A0P A5Figure 5-35Example 3: Aluminium welding of different sheet metal thicknesses (non-latched or latchedspecial)ItP A0P A1P A8P A9tFigure 5-36NOTEUp to 16 programs (P A0to P A15) can be defined.An operating point (wire speed, arc length correction, dynamics/choke effect) can be definedpermanently in each program.Program P0 is an exception: the settings for operating points are made manually here.Changes to the welding parameters are saved immediately!66099-005234-EW50116.04.2012