BRIDGE REPAIR/REHABILITATION FEASIBILITY STUDY

Bridge Repair_Rehabilitation Feasibility Study - Town to Chatham

Bridge Repair_Rehabilitation Feasibility Study - Town to Chatham

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

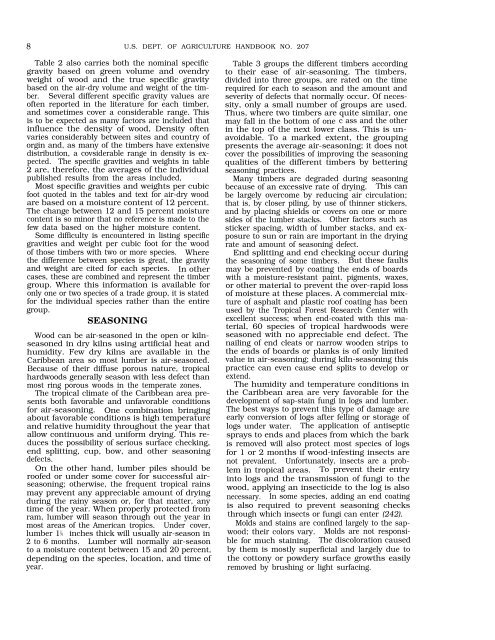

8 U.S. DEPT. OF AGRICULTURE HANDBOOK NO. 207<br />

Table 2 also carries both the nominal specific<br />

gravity based on green volume and ovendry<br />

weight of wood and the true specific gravity<br />

based on the air-dry volume and weight of the timber.<br />

Several different specific gravity values are<br />

often reported in the literature for each timber,<br />

and sometimes cover a considerable range. This<br />

is to be expected as many factors are included that<br />

influence the density of wood, Density often<br />

varies considerably between sites and country of<br />

orgin and, as many of the timbers have extensive<br />

distribution, a covsiderable range in density is expected.<br />

The specific gravities and weights in table<br />

2 are, therefore, the averages of the individual<br />

published results from the areas included,<br />

Most specific gravities and weights per cubic<br />

foot quoted in the tables and text for air-dry wood<br />

are based on a moisture content of 12 percent.<br />

The change between 12 and 15 percent moisture<br />

content is so minor that no reference is made to the<br />

few data based on the higher moisture content.<br />

Some difficulty is encountered in listing specific<br />

gravities and weight per cubic foot for the wood<br />

of those timbers with two or more species. Where<br />

the difference between species is great, the gravity<br />

and weight are cited for each species. In other<br />

cases, these are combined and represent the timber<br />

group. Where this information is available for<br />

only one or two species of a trade group, it is stated<br />

for the individual species rather than the entire<br />

group.<br />

SEASONING<br />

Wood can be air-seasoned in the open or kilnseasoned<br />

in dry kilns using artificial heat and<br />

humidity. Few dry kilns are available in the<br />

Caribbean area so most lumber is air-seasoned.<br />

Because of their diffuse porous nature, tropical<br />

hardwoods generally season with less defect than<br />

most ring porous woods in the temperate zones.<br />

The tropical climate of the Caribbean area presents<br />

both favorable and unfavorable conditions<br />

for air-seasoning. One combination bringing<br />

about favorable conditions is high temperature<br />

and relative humidity throughout the year that<br />

allow continuous and uniform drying. This reduces<br />

the possibility of serious surface checking,<br />

end splitting, cup, bow, and other seasoning<br />

defects.<br />

On the other hand, lumber piles should be<br />

roofed or under some cover for successful airseasoning;<br />

otherwise, the frequent tropical rains<br />

may prevent any appreciable amount of drying<br />

during the rainy season or, for that matter, any<br />

time of the year. When properly protected from<br />

ram, lumber will season through out the year in<br />

most areas of the American tropics. Under cover,<br />

lumber 1¼ inches thick will usually air-season in<br />

2 to 6 months. Lumber will normally air-season<br />

to a moisture content between 15 and 20 percent,<br />

depending on the species, location, and time of<br />

year.<br />

Table 3 groups the different timbers according<br />

to their ease of air-seasoning. The timbers,<br />

divided into three groups, are rated on the time<br />

required for each to season and the amount and<br />

severity of defects that normally occur. Of necessity,<br />

only a small number of groups are used.<br />

Thus, where two timbers are quite similar, one<br />

may fall in the bottom of one c ass and the other<br />

in the top of the next lower class. This is unavoidable.<br />

To a marked extent, the grouping<br />

presents the average air-seasoning; it does not<br />

cover the possibilities of improving the seasoning<br />

qualities of the different timbers by bettering<br />

seasoning practices.<br />

Many timbers are degraded during seasoning<br />

because of an excessive rate of drying. This can<br />

be largely overcome by reducing air circulation;<br />

that is, by closer piling, by use of thinner stickers,<br />

and by placing shields or covers on one or more<br />

sides of the lumber stacks. Other factors such as<br />

sticker spacing, width of lumber stacks, and exposure<br />

to sun or rain are important in the drying<br />

rate and amount of seasoning defect.<br />

End splitting and end checking occur during<br />

the seasoning of some timbers. But these faults<br />

may be prevented by coating the ends of boards<br />

with a moisture-resistant paint, pigments, waxes,<br />

or other material to prevent the over-rapid loss<br />

of moisture at these places. A commercial mixture<br />

of asphalt and plastic roof coating has been<br />

used by the Tropical Forest Research Center with<br />

excellent success; when end-coated with this material,<br />

60 species of tropical hardwoods were<br />

seasoned with no appreciable end defect. The<br />

nailing of end cleats or narrow wooden strips to<br />

the ends of boards or planks is of only limited<br />

value in air-seasoning; during kiln-seasoning this<br />

practice can even cause end splits to develop or<br />

extend.<br />

The humidity and temperature conditions in<br />

the Caribbean area are very favorable for the<br />

development of sap-stain fungi in logs and lumber.<br />

The best ways to prevent this type of damage are<br />

early conversion of logs after felling or storage of<br />

logs under water. The application of antiseptic<br />

sprays to ends and places from which the bark<br />

is removed will also protect most species of logs<br />

for 1 or 2 months if wood-infesting insects are<br />

not prevalent. Unfortunately, insects are a problem<br />

in tropical areas. To prevent their entry<br />

into logs and the transmission of fungi to the<br />

wood, applying an insecticide to the log is also<br />

necessary. In some species, adding an end coating<br />

is also required to prevent seasoning checks<br />

through which insects or fungi can enter (242).<br />

Molds and stains are confined largely to the sapwood;<br />

their colors vary. Molds are not responsible<br />

for much staining. The discoloration caused<br />

by them is mostly superficial and largely due to<br />

the cottony or powdery surface growths easily<br />

removed by brushing or light surfacing.