BRIDGE REPAIR/REHABILITATION FEASIBILITY STUDY

Bridge Repair_Rehabilitation Feasibility Study - Town to Chatham

Bridge Repair_Rehabilitation Feasibility Study - Town to Chatham

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

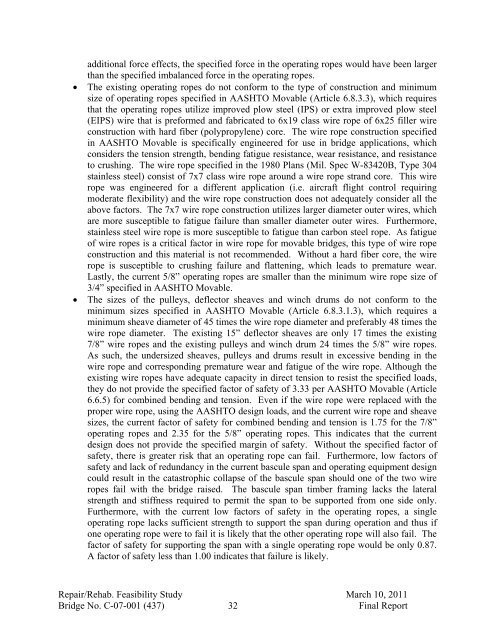

additional force effects, the specified force in the operating ropes would have been larger<br />

than the specified imbalanced force in the operating ropes.<br />

• The existing operating ropes do not conform to the type of construction and minimum<br />

size of operating ropes specified in AASHTO Movable (Article 6.8.3.3), which requires<br />

that the operating ropes utilize improved plow steel (IPS) or extra improved plow steel<br />

(EIPS) wire that is preformed and fabricated to 6x19 class wire rope of 6x25 filler wire<br />

construction with hard fiber (polypropylene) core. The wire rope construction specified<br />

in AASHTO Movable is specifically engineered for use in bridge applications, which<br />

considers the tension strength, bending fatigue resistance, wear resistance, and resistance<br />

to crushing. The wire rope specified in the 1980 Plans (Mil. Spec W-83420B, Type 304<br />

stainless steel) consist of 7x7 class wire rope around a wire rope strand core. This wire<br />

rope was engineered for a different application (i.e. aircraft flight control requiring<br />

moderate flexibility) and the wire rope construction does not adequately consider all the<br />

above factors. The 7x7 wire rope construction utilizes larger diameter outer wires, which<br />

are more susceptible to fatigue failure than smaller diameter outer wires. Furthermore,<br />

stainless steel wire rope is more susceptible to fatigue than carbon steel rope. As fatigue<br />

of wire ropes is a critical factor in wire rope for movable bridges, this type of wire rope<br />

construction and this material is not recommended. Without a hard fiber core, the wire<br />

rope is susceptible to crushing failure and flattening, which leads to premature wear.<br />

Lastly, the current 5/8” operating ropes are smaller than the minimum wire rope size of<br />

3/4” specified in AASHTO Movable.<br />

• The sizes of the pulleys, deflector sheaves and winch drums do not conform to the<br />

minimum sizes specified in AASHTO Movable (Article 6.8.3.1.3), which requires a<br />

minimum sheave diameter of 45 times the wire rope diameter and preferably 48 times the<br />

wire rope diameter. The existing 15” deflector sheaves are only 17 times the existing<br />

7/8” wire ropes and the existing pulleys and winch drum 24 times the 5/8” wire ropes.<br />

As such, the undersized sheaves, pulleys and drums result in excessive bending in the<br />

wire rope and corresponding premature wear and fatigue of the wire rope. Although the<br />

existing wire ropes have adequate capacity in direct tension to resist the specified loads,<br />

they do not provide the specified factor of safety of 3.33 per AASHTO Movable (Article<br />

6.6.5) for combined bending and tension. Even if the wire rope were replaced with the<br />

proper wire rope, using the AASHTO design loads, and the current wire rope and sheave<br />

sizes, the current factor of safety for combined bending and tension is 1.75 for the 7/8”<br />

operating ropes and 2.35 for the 5/8” operating ropes. This indicates that the current<br />

design does not provide the specified margin of safety. Without the specified factor of<br />

safety, there is greater risk that an operating rope can fail. Furthermore, low factors of<br />

safety and lack of redundancy in the current bascule span and operating equipment design<br />

could result in the catastrophic collapse of the bascule span should one of the two wire<br />

ropes fail with the bridge raised. The bascule span timber framing lacks the lateral<br />

strength and stiffness required to permit the span to be supported from one side only.<br />

Furthermore, with the current low factors of safety in the operating ropes, a single<br />

operating rope lacks sufficient strength to support the span during operation and thus if<br />

one operating rope were to fail it is likely that the other operating rope will also fail. The<br />

factor of safety for supporting the span with a single operating rope would be only 0.87.<br />

A factor of safety less than 1.00 indicates that failure is likely.<br />

Repair/Rehab. Feasibility Study March 10, 2011<br />

Bridge No. C-07-001 (437) 32 Final Report