BRIDGE REPAIR/REHABILITATION FEASIBILITY STUDY

Bridge Repair_Rehabilitation Feasibility Study - Town to Chatham

Bridge Repair_Rehabilitation Feasibility Study - Town to Chatham

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

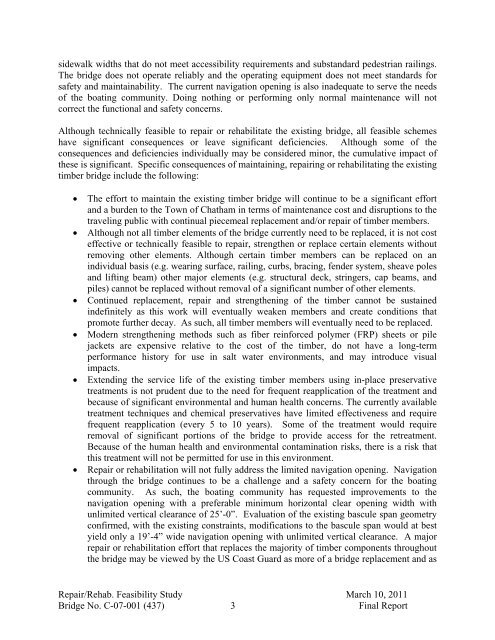

sidewalk widths that do not meet accessibility requirements and substandard pedestrian railings.<br />

The bridge does not operate reliably and the operating equipment does not meet standards for<br />

safety and maintainability. The current navigation opening is also inadequate to serve the needs<br />

of the boating community. Doing nothing or performing only normal maintenance will not<br />

correct the functional and safety concerns.<br />

Although technically feasible to repair or rehabilitate the existing bridge, all feasible schemes<br />

have significant consequences or leave significant deficiencies. Although some of the<br />

consequences and deficiencies individually may be considered minor, the cumulative impact of<br />

these is significant. Specific consequences of maintaining, repairing or rehabilitating the existing<br />

timber bridge include the following:<br />

• The effort to maintain the existing timber bridge will continue to be a significant effort<br />

and a burden to the Town of Chatham in terms of maintenance cost and disruptions to the<br />

traveling public with continual piecemeal replacement and/or repair of timber members.<br />

• Although not all timber elements of the bridge currently need to be replaced, it is not cost<br />

effective or technically feasible to repair, strengthen or replace certain elements without<br />

removing other elements. Although certain timber members can be replaced on an<br />

individual basis (e.g. wearing surface, railing, curbs, bracing, fender system, sheave poles<br />

and lifting beam) other major elements (e.g. structural deck, stringers, cap beams, and<br />

piles) cannot be replaced without removal of a significant number of other elements.<br />

• Continued replacement, repair and strengthening of the timber cannot be sustained<br />

indefinitely as this work will eventually weaken members and create conditions that<br />

promote further decay. As such, all timber members will eventually need to be replaced.<br />

• Modern strengthening methods such as fiber reinforced polymer (FRP) sheets or pile<br />

jackets are expensive relative to the cost of the timber, do not have a long-term<br />

performance history for use in salt water environments, and may introduce visual<br />

impacts.<br />

• Extending the service life of the existing timber members using in-place preservative<br />

treatments is not prudent due to the need for frequent reapplication of the treatment and<br />

because of significant environmental and human health concerns. The currently available<br />

treatment techniques and chemical preservatives have limited effectiveness and require<br />

frequent reapplication (every 5 to 10 years). Some of the treatment would require<br />

removal of significant portions of the bridge to provide access for the retreatment.<br />

Because of the human health and environmental contamination risks, there is a risk that<br />

this treatment will not be permitted for use in this environment.<br />

• Repair or rehabilitation will not fully address the limited navigation opening. Navigation<br />

through the bridge continues to be a challenge and a safety concern for the boating<br />

community. As such, the boating community has requested improvements to the<br />

navigation opening with a preferable minimum horizontal clear opening width with<br />

unlimited vertical clearance of 25’-0”. Evaluation of the existing bascule span geometry<br />

confirmed, with the existing constraints, modifications to the bascule span would at best<br />

yield only a 19’-4” wide navigation opening with unlimited vertical clearance. A major<br />

repair or rehabilitation effort that replaces the majority of timber components throughout<br />

the bridge may be viewed by the US Coast Guard as more of a bridge replacement and as<br />

Repair/Rehab. Feasibility Study March 10, 2011<br />

Bridge No. C-07-001 (437) 3 Final Report