BRIDGE REPAIR/REHABILITATION FEASIBILITY STUDY

Bridge Repair_Rehabilitation Feasibility Study - Town to Chatham

Bridge Repair_Rehabilitation Feasibility Study - Town to Chatham

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

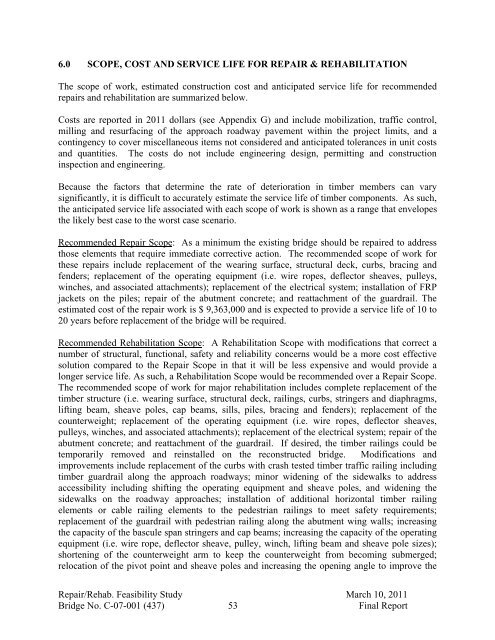

6.0 SCOPE, COST AND SERVICE LIFE FOR <strong>REPAIR</strong> & <strong>REHABILITATION</strong><br />

The scope of work, estimated construction cost and anticipated service life for recommended<br />

repairs and rehabilitation are summarized below.<br />

Costs are reported in 2011 dollars (see Appendix G) and include mobilization, traffic control,<br />

milling and resurfacing of the approach roadway pavement within the project limits, and a<br />

contingency to cover miscellaneous items not considered and anticipated tolerances in unit costs<br />

and quantities. The costs do not include engineering design, permitting and construction<br />

inspection and engineering.<br />

Because the factors that determine the rate of deterioration in timber members can vary<br />

significantly, it is difficult to accurately estimate the service life of timber components. As such,<br />

the anticipated service life associated with each scope of work is shown as a range that envelopes<br />

the likely best case to the worst case scenario.<br />

Recommended Repair Scope: As a minimum the existing bridge should be repaired to address<br />

those elements that require immediate corrective action. The recommended scope of work for<br />

these repairs include replacement of the wearing surface, structural deck, curbs, bracing and<br />

fenders; replacement of the operating equipment (i.e. wire ropes, deflector sheaves, pulleys,<br />

winches, and associated attachments); replacement of the electrical system; installation of FRP<br />

jackets on the piles; repair of the abutment concrete; and reattachment of the guardrail. The<br />

estimated cost of the repair work is $ 9,363,000 and is expected to provide a service life of 10 to<br />

20 years before replacement of the bridge will be required.<br />

Recommended Rehabilitation Scope: A Rehabilitation Scope with modifications that correct a<br />

number of structural, functional, safety and reliability concerns would be a more cost effective<br />

solution compared to the Repair Scope in that it will be less expensive and would provide a<br />

longer service life. As such, a Rehabilitation Scope would be recommended over a Repair Scope.<br />

The recommended scope of work for major rehabilitation includes complete replacement of the<br />

timber structure (i.e. wearing surface, structural deck, railings, curbs, stringers and diaphragms,<br />

lifting beam, sheave poles, cap beams, sills, piles, bracing and fenders); replacement of the<br />

counterweight; replacement of the operating equipment (i.e. wire ropes, deflector sheaves,<br />

pulleys, winches, and associated attachments); replacement of the electrical system; repair of the<br />

abutment concrete; and reattachment of the guardrail. If desired, the timber railings could be<br />

temporarily removed and reinstalled on the reconstructed bridge. Modifications and<br />

improvements include replacement of the curbs with crash tested timber traffic railing including<br />

timber guardrail along the approach roadways; minor widening of the sidewalks to address<br />

accessibility including shifting the operating equipment and sheave poles, and widening the<br />

sidewalks on the roadway approaches; installation of additional horizontal timber railing<br />

elements or cable railing elements to the pedestrian railings to meet safety requirements;<br />

replacement of the guardrail with pedestrian railing along the abutment wing walls; increasing<br />

the capacity of the bascule span stringers and cap beams; increasing the capacity of the operating<br />

equipment (i.e. wire rope, deflector sheave, pulley, winch, lifting beam and sheave pole sizes);<br />

shortening of the counterweight arm to keep the counterweight from becoming submerged;<br />

relocation of the pivot point and sheave poles and increasing the opening angle to improve the<br />

Repair/Rehab. Feasibility Study March 10, 2011<br />

Bridge No. C-07-001 (437) 53 Final Report