BRIDGE REPAIR/REHABILITATION FEASIBILITY STUDY

Bridge Repair_Rehabilitation Feasibility Study - Town to Chatham

Bridge Repair_Rehabilitation Feasibility Study - Town to Chatham

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

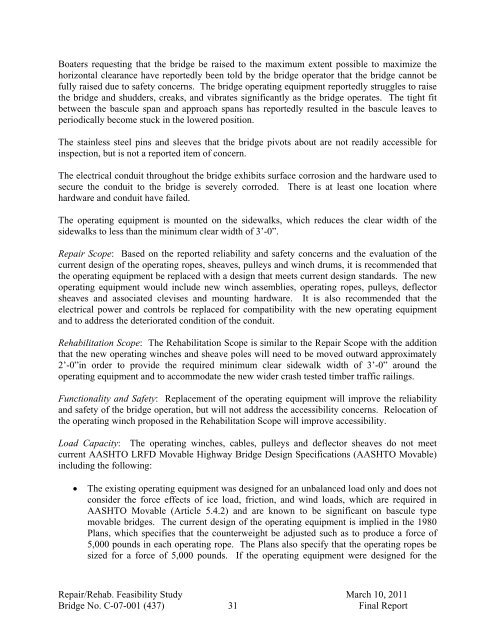

Boaters requesting that the bridge be raised to the maximum extent possible to maximize the<br />

horizontal clearance have reportedly been told by the bridge operator that the bridge cannot be<br />

fully raised due to safety concerns. The bridge operating equipment reportedly struggles to raise<br />

the bridge and shudders, creaks, and vibrates significantly as the bridge operates. The tight fit<br />

between the bascule span and approach spans has reportedly resulted in the bascule leaves to<br />

periodically become stuck in the lowered position.<br />

The stainless steel pins and sleeves that the bridge pivots about are not readily accessible for<br />

inspection, but is not a reported item of concern.<br />

The electrical conduit throughout the bridge exhibits surface corrosion and the hardware used to<br />

secure the conduit to the bridge is severely corroded. There is at least one location where<br />

hardware and conduit have failed.<br />

The operating equipment is mounted on the sidewalks, which reduces the clear width of the<br />

sidewalks to less than the minimum clear width of 3’-0”.<br />

Repair Scope: Based on the reported reliability and safety concerns and the evaluation of the<br />

current design of the operating ropes, sheaves, pulleys and winch drums, it is recommended that<br />

the operating equipment be replaced with a design that meets current design standards. The new<br />

operating equipment would include new winch assemblies, operating ropes, pulleys, deflector<br />

sheaves and associated clevises and mounting hardware. It is also recommended that the<br />

electrical power and controls be replaced for compatibility with the new operating equipment<br />

and to address the deteriorated condition of the conduit.<br />

Rehabilitation Scope: The Rehabilitation Scope is similar to the Repair Scope with the addition<br />

that the new operating winches and sheave poles will need to be moved outward approximately<br />

2’-0”in order to provide the required minimum clear sidewalk width of 3’-0” around the<br />

operating equipment and to accommodate the new wider crash tested timber traffic railings.<br />

Functionality and Safety: Replacement of the operating equipment will improve the reliability<br />

and safety of the bridge operation, but will not address the accessibility concerns. Relocation of<br />

the operating winch proposed in the Rehabilitation Scope will improve accessibility.<br />

Load Capacity: The operating winches, cables, pulleys and deflector sheaves do not meet<br />

current AASHTO LRFD Movable Highway Bridge Design Specifications (AASHTO Movable)<br />

including the following:<br />

• The existing operating equipment was designed for an unbalanced load only and does not<br />

consider the force effects of ice load, friction, and wind loads, which are required in<br />

AASHTO Movable (Article 5.4.2) and are known to be significant on bascule type<br />

movable bridges. The current design of the operating equipment is implied in the 1980<br />

Plans, which specifies that the counterweight be adjusted such as to produce a force of<br />

5,000 pounds in each operating rope. The Plans also specify that the operating ropes be<br />

sized for a force of 5,000 pounds. If the operating equipment were designed for the<br />

Repair/Rehab. Feasibility Study March 10, 2011<br />

Bridge No. C-07-001 (437) 31 Final Report