Materials for engineering, 3rd Edition - (Malestrom)

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

222<br />

<strong>Materials</strong> <strong>for</strong> <strong>engineering</strong><br />

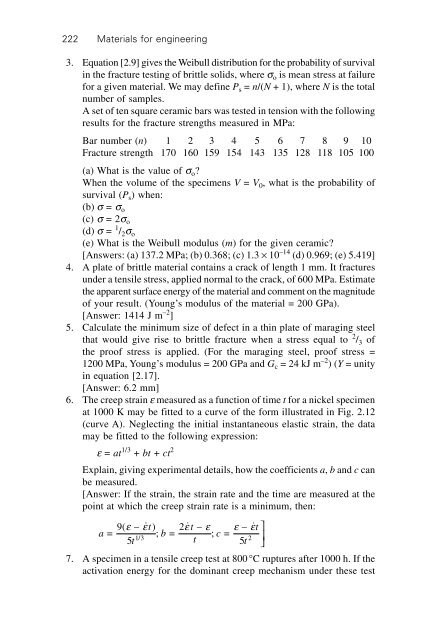

3. Equation [2.9] gives the Weibull distribution <strong>for</strong> the probability of survival<br />

in the fracture testing of brittle solids, where σ o is mean stress at failure<br />

<strong>for</strong> a given material. We may define P s = n/(N + 1), where N is the total<br />

number of samples.<br />

A set of ten square ceramic bars was tested in tension with the following<br />

results <strong>for</strong> the fracture strengths measured in MPa:<br />

Bar number (n) 1 2 3 4 5 6 7 8 9 10<br />

Fracture strength 170 160 159 154 143 135 128 118 105 100<br />

(a) What is the value of σ o ?<br />

When the volume of the specimens V = V 0 , what is the probability of<br />

survival (P s ) when:<br />

(b) σ = σ o<br />

(c) σ = 2σ o<br />

(d) σ = 1 / 2 σ o<br />

(e) What is the Weibull modulus (m) <strong>for</strong> the given ceramic?<br />

[Answers: (a) 137.2 MPa; (b) 0.368; (c) 1.3 × 10 –14 (d) 0.969; (e) 5.419]<br />

4. A plate of brittle material contains a crack of length 1 mm. It fractures<br />

under a tensile stress, applied normal to the crack, of 600 MPa. Estimate<br />

the apparent surface energy of the material and comment on the magnitude<br />

of your result. (Young’s modulus of the material = 200 GPa).<br />

[Answer: 1414 J m –2 ]<br />

5. Calculate the minimum size of defect in a thin plate of maraging steel<br />

that would give rise to brittle fracture when a stress equal to 2 / 3 of<br />

the proof stress is applied. (For the maraging steel, proof stress =<br />

1200 MPa, Young’s modulus = 200 GPa and G c = 24 kJ m –2 ) (Y = unity<br />

in equation [2.17].<br />

[Answer: 6.2 mm]<br />

6. The creep strain ε measured as a function of time t <strong>for</strong> a nickel specimen<br />

at 1000 K may be fitted to a curve of the <strong>for</strong>m illustrated in Fig. 2.12<br />

(curve A). Neglecting the initial instantaneous elastic strain, the data<br />

may be fitted to the following expression:<br />

ε = at 1/3 + bt + ct 2<br />

Explain, giving experimental details, how the coefficients a, b and c can<br />

be measured.<br />

[Answer: If the strain, the strain rate and the time are measured at the<br />

point at which the creep strain rate is a minimum, then:<br />

t t<br />

t<br />

a = 9( ε – ˙ ε ) ; b = 2 ˙ ε – ε ε<br />

; c = – ˙ ε ⎤<br />

1/3<br />

5t<br />

t<br />

2<br />

5t<br />

⎥<br />

⎦<br />

7. A specimen in a tensile creep test at 800°C ruptures after 1000 h. If the<br />

activation energy <strong>for</strong> the dominant creep mechanism under these test