Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Pfeiffer <strong>Vacuum</strong><br />

Page 32<br />

Model<br />

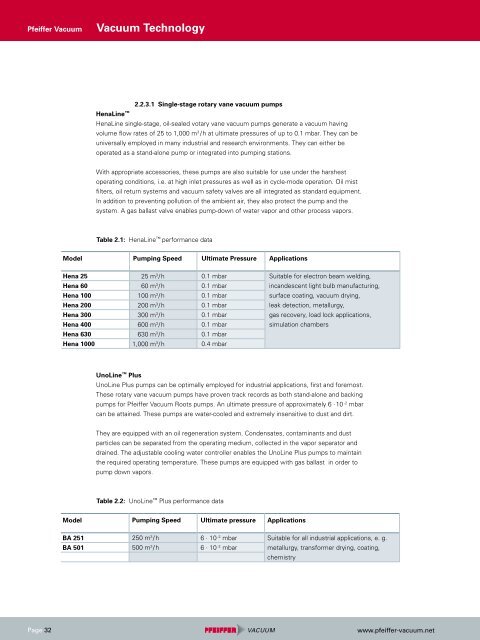

Hena 25<br />

Hena 60<br />

Hena 100<br />

Hena 200<br />

Hena 300<br />

Hena 400<br />

Hena 630<br />

Hena 1000<br />

Model<br />

BA 251<br />

BA 501<br />

<strong>Vacuum</strong> <strong>Technology</strong><br />

HenaLine <br />

2.2.3.1 Single-stage rotary vane vacuum pumps<br />

HenaLine single-stage, oil-sealed votary vane vacuum pumps generate a vacuum having<br />

volume flow rates of 25 to 1,000 m3 / h at ultimate pressures of up to 0.1 mbar. They can be<br />

universally employed in many industrial and research environments. They can either be<br />

operated as a stand-alone pump or integrated into pumping stations.<br />

With appropriate accessories, these pumps are also suitable for use under the harshest<br />

operating conditions, i.e. at high inlet pressures as well as in cycle-mode operation. Oil mist<br />

filters, oil return systems and vacuum safety valves are all integrated as standard equipment.<br />

In addition to preventing pollution of the ambient air, they also protect the pump and the<br />

system. A gas ballast valve enables pump-down of water vapor and other process vapors.<br />

Table 2.1: HenaLine performance data<br />

UnoLine Plus<br />

Pumping Speed<br />

25 m 3 / h<br />

60 m 3 / h<br />

100 m 3 / h<br />

200 m 3 / h<br />

300 m 3 / h<br />

600 m 3 / h<br />

630 m 3 / h<br />

1,000 m 3 / h<br />

UnoLine Plus pumps can be optimally employed for industrial applications, first and foremost.<br />

These rotary vane vacuum pumps have proven track records as both stand-alone and backing<br />

pumps for Pfeiffer <strong>Vacuum</strong> Roots pumps. An ultimate pressure of approximately 6 . 10 -2 mbar<br />

can be attained. These pumps are water-cooled and extremely insensitive to dust and dirt.<br />

They are equipped with an oil regeneration system. Condensates, contaminants and dust<br />

particles can be separated from the operating medium, collected in the vapor separator and<br />

drained. The adjustable cooling water controller enables the UnoLine Plus pumps to maintain<br />

the required operating temperature. These pumps are equipped with gas ballast in order to<br />

pump down vapors.<br />

Table 2.2: UnoLine Plus performance data<br />

Pumping Speed<br />

250 m3 / h<br />

500 m3 / h<br />

Ultimate Pressure<br />

0.1 mbar<br />

0.1 mbar<br />

0.1 mbar<br />

0.1 mbar<br />

0.1 mbar<br />

0.1 mbar<br />

0.1 mbar<br />

0.4 mbar<br />

Ultimate pressure<br />

6 . 10 -2 mbar<br />

6 . 10 -2 mbar<br />

Applications<br />

Suitable for electron beam welding,<br />

incandescent light bulb manufacturing,<br />

surface coating, vacuum drying,<br />

leak detection, metallurgy,<br />

gas recovery, load lock applications,<br />

simulation chambers<br />

Applications<br />

Suitable for all industrial applications, e. g.<br />

metallurgy, transformer drying, coating,<br />

chemistry<br />

www.pfeiffer-vacuum.net