Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Model<br />

XtraDry 150-2<br />

XtraDry 250-1<br />

www.pfeiffer-vacuum.net<br />

Gas ballast air can be admitted to the crankcase via the gas ballast valve and the throttling<br />

port behind it in order to displace water vapor though the pump without condensation (see<br />

also 2.1.6, Gas ballast).<br />

In the case of dry piston pumps, wear occurs on the piston seals during operation, particularly<br />

at high average piston speeds. Once the required inlet pressure is reached, seal wear can be<br />

significantly reduced by lowering the RPM.<br />

2.4.2 Applications<br />

Dry piston pumps have higher pumping speeds than those offered by diaphragm pumps, and<br />

are used where a clean, hydrocarbon-free vacuum is required when operating near ultimate<br />

pressure. Eliminating the inlet valve enables lower base pressures to be reached than with<br />

diaphragm pumps. Like all true positive-displacement pumps, piston pumps have the same<br />

pumping speed for all gases.<br />

Piston pumps are suitable for use as dry backing pumps for turbomolecular pumps. <strong>How</strong>ever<br />

to prevent enrichment of hydrogen and water vapor in the backing vacuum area of the turbopump,<br />

they must be operated with gas ballast if necessary. Piston pumps are particularly well<br />

suited for analytical applications and for leak detectors (see also 5.2, Design of a helium leak<br />

detector). If the test specimens are directly evacuated by the backing pump for leak detection,<br />

they cannot be contaminated with oil vapor when a dry backing pump is used.<br />

Piston pumps are not suitable for pumping corrosive or abrasive media.<br />

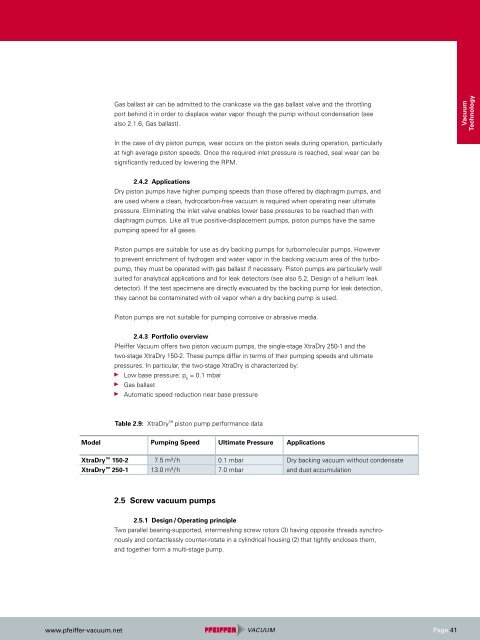

2.4.3 Portfolio overview<br />

Pfeiffer <strong>Vacuum</strong> offers two piston vacuum pumps, the single-stage XtraDry 250-1 and the<br />

two-stage XtraDry 150-2. These pumps differ in terms of their pumping speeds and ultimate<br />

pressures. In particular, the two-stage XtraDry is characterized by:<br />

Low base pressure: p b = 0.1 mbar<br />

Gas ballast<br />

Automatic speed reduction near base pressure<br />

Table 2.9: XtraDry piston pump performance data<br />

Pumping Speed<br />

7.5 m³ / h<br />

13.0 m³ / h<br />

2.5 Screw vacuum pumps<br />

2.5.1 Design / Operating principle<br />

Ultimate Pressure<br />

0.1 mbar<br />

7.0 mbar<br />

Applications<br />

Dry backing vacuum without condensate<br />

and dust accumulation<br />

Two parallel bearing-supported, intermeshing screw rotors (3) having opposite threads synchronously<br />

and contactlessly counter-rotate in a cylindrical housing (2) that tightly encloses them,<br />

and together form a multi-stage pump.<br />

Page 41<br />

<strong>Vacuum</strong><br />

<strong>Technology</strong>