Engine Management Systems - Denso-am.eu

Engine Management Systems - Denso-am.eu

Engine Management Systems - Denso-am.eu

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

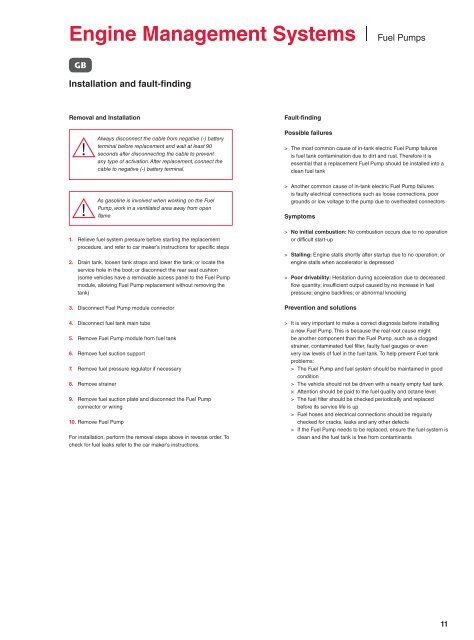

<strong>Engine</strong> <strong>Management</strong> <strong>Systems</strong>Fuel PumpsGBInstallation and fault-findingRemoval and Installation1. Relieve fuel system pressure before starting the replacementprocedure, and refer to car maker’s instructions for specific steps2. Drain tank, loosen tank straps and lower the tank; or locate theservice hole in the boot; or disconnect the rear seat cushion(some vehicles have a removable access panel to the Fuel Pumpmodule, allowing Fuel Pump replacement without removing thetank)3. Disconnect Fuel Pump module connector4. Disconnect fuel tank main tube5. Remove Fuel Pump module from fuel tank6. Remove fuel suction support7. Remove fuel pressure regulator if necessary8. Remove strainerAlways disconnect the cable from negative (-) batteryterminal before replacement and wait at least 90seconds after disconnecting the cable to preventany type of activation. After replacement, connect thecable to negative (-) battery terminal.As gasoline is involved when working on the FuelPump, work in a ventilated area away from openfl<strong>am</strong>e9. Remove fuel suction plate and disconnect the Fuel Pumpconnector or wiring10. Remove Fuel PumpFor installation, perform the removal steps above in reverse order. Tocheck for fuel leaks refer to the car maker’s instructions.Fault-findingPossible failures> The most common cause of in-tank electric Fuel Pump failuresis fuel tank cont<strong>am</strong>ination due to dirt and rust. Therefore it isessential that a replacement Fuel Pump should be installed into aclean fuel tank> Another common cause of in-tank electric Fuel Pump failuresis faulty electrical connections such as loose connections, poorgrounds or low voltage to the pump due to overheated connectorsSymptoms> No initial combustion: No combustion occurs due to no operationor difficult start-up> Stalling: <strong>Engine</strong> stalls shortly after startup due to no operation; orengine stalls when accelerator is depressed> Poor drivability: Hesitation during acceleration due to decreasedflow quantity; insufficient output caused by no increase in fuelpressure; engine backfires; or abnormal knockingPrevention and solutions> It is very important to make a correct diagnosis before installinga new Fuel Pump. This is because the real root cause mightbe another component than the Fuel Pump, such as a cloggedstrainer, cont<strong>am</strong>inated fuel filter, faulty fuel gauges or evenvery low levels of fuel in the fuel tank. To help prevent Fuel tankproblems:> The Fuel Pump and fuel system should be maintained in goodcondition> The vehicle should not be driven with a nearly empty fuel tank> Attention should be paid to the fuel quality and octane level> The fuel filter should be checked periodically and replacedbefore its service life is up> Fuel hoses and electrical connections should be regularlychecked for cracks, leaks and any other defects> If the Fuel Pump needs to be replaced, ensure the fuel system isclean and the fuel tank is free from cont<strong>am</strong>inants11