manuale per l'installatore - 1/3 tipologie d'installazione - 2/3 software ...

manuale per l'installatore - 1/3 tipologie d'installazione - 2/3 software ...

manuale per l'installatore - 1/3 tipologie d'installazione - 2/3 software ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

4.2.1.6 Oxygen Sensor<br />

Calibration<br />

It is the fifth step for LPG installation<br />

and the sixth one for CNG<br />

(see picture 4.1).<br />

The Oxygen sensor calibration<br />

is very important for this system as<br />

this signal is used to speed up and<br />

optimize the self-learning strategy.<br />

It is important to know some<br />

oxygen sensor characteristics such<br />

as if it is a “CURRENT” or a “VOLT-<br />

AGE” one (ordinary oxygen sensor),<br />

if it is “straight” or “reverse”.<br />

Let’s explain the meaning:<br />

• Straight Oxygen sensor: the<br />

high tension level corresponds<br />

to a “rich” situation of the mixture<br />

and, on the contrary, the<br />

low tension level to a “lean” situation<br />

of the mixture.<br />

• Reverse Oxygen sensor: the<br />

opposite of Straight one.<br />

Note: usually if the oxygen sensor<br />

is a current type, it is a reverse<br />

one, too.<br />

Identification method: with a<br />

sharp acceleration and standing<br />

still, execute a cut- off (released<br />

condition where there is no injection);<br />

if the oxygen sensor is low it<br />

is a Straight one otherwise it is a<br />

Reverse one.<br />

The Current oxygen sensor is<br />

recognisable for its extremely different<br />

behaviour compared to the<br />

Voltage oxygen sensor one.<br />

During stationary conditions (at<br />

idle) when the vehicle is in control,<br />

a voltage oxygen sensor continuously<br />

varies between minimum and<br />

maximum tension value while a<br />

current one will keep practically the<br />

same value.<br />

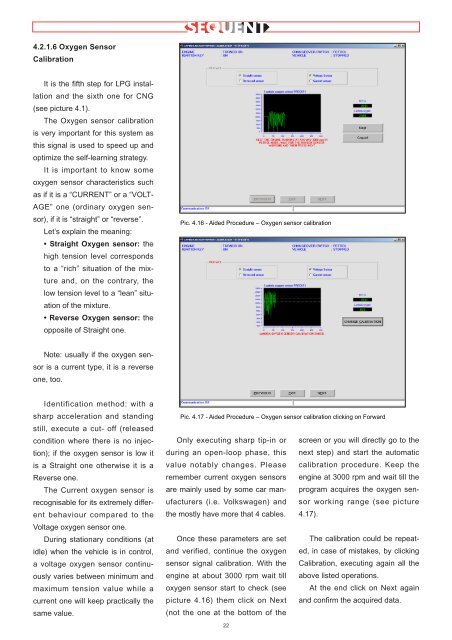

Pic. 4.16 - Aided Procedure – Oxygen sensor calibration<br />

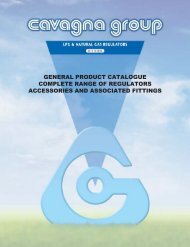

Pic. 4.17 - Aided Procedure – Oxygen sensor calibration clicking on Forward<br />

Only executing sharp tip-in or<br />

during an open-loop phase, this<br />

value notably changes. Please<br />

remember current oxygen sensors<br />

are mainly used by some car manufacturers<br />

(i.e. Volkswagen) and<br />

the mostly have more that 4 cables.<br />

Once these parameters are set<br />

and verified, continue the oxygen<br />

sensor signal calibration. With the<br />

engine at about 3000 rpm wait till<br />

oxygen sensor start to check (see<br />

picture 4.16) them click on Next<br />

(not the one at the bottom of the<br />

22<br />

screen or you will directly go to the<br />

next step) and start the automatic<br />

calibration procedure. Keep the<br />

engine at 3000 rpm and wait till the<br />

program acquires the oxygen sensor<br />

working range (see picture<br />

4.17).<br />

The calibration could be repeated,<br />

in case of mistakes, by clicking<br />

Calibration, executing again all the<br />

above listed o<strong>per</strong>ations.<br />

At the end click on Next again<br />

and confirm the acquired data.