LIBRARY ı6ıul 0) - Cranfield University

LIBRARY ı6ıul 0) - Cranfield University

LIBRARY ı6ıul 0) - Cranfield University

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

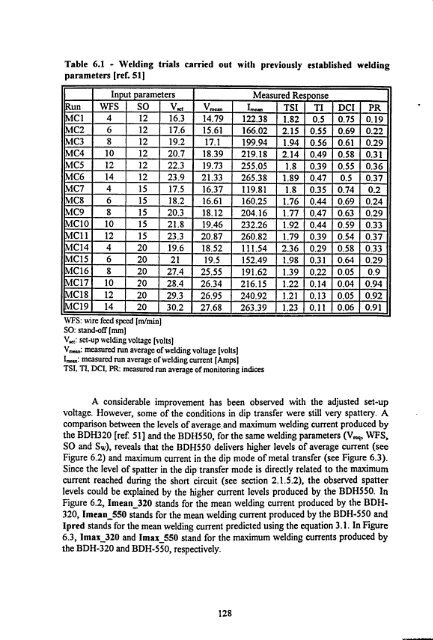

Table 6.1 - Welding trials carried out with previously established welding<br />

parameters [ref. 511<br />

In ut parameters<br />

Measured Res onse<br />

Run WFS SO Vt Vmean IfficaJ TSI TI DCI PR<br />

MCI 4 12 16.3 14.79 122.38 1.82 0.5 0.75 0.19<br />

C2 6 12 17.6 15.61 166.02 2.15 0.55 0.69 0.22<br />

C3 8 12 19.2 17.1 199.94 1.94 0.56 0.61 0.29<br />

C4 10 12 20.7 18.39 219.18 2.14 0.49 0.58 0.31<br />

C5 12 12 22.3 19.73 255.05 1.8 0.39 0.55 0.36<br />

C6 14 12 23.9 21.33 265.38 1.89 0.47 0.5 0.37<br />

C7 4 15 17.5 16.37 119.81 1.8 0.35 0.74 0.2<br />

C8 6 15 18.2 16.61 160.25 1.76 0.44 0.69 0.24<br />

C9 8 15 20.3 18.12 204.16 1.77 0.47 0.63 0.29<br />

C10 10 15 21.8 19.46 232.26 1.92 0.44 0.59 0.33<br />

C11 12 15 23.3 20.87 260.82 1.79 0.39 0.54 0.37<br />

C14 4 20 19.6 18.52 111.54 2.36 0.29 0.58 0.33<br />

4C15 6 20 21 19.5 152.49 1.98 0.31 0.64 0.29<br />

C16 8 20 27.4 25.55 191.62 1.39 0.22 0.05 0.9<br />

MC 17 10 20 28.4 26.34 216.15 1.22 0.14 0.04 0.94<br />

MC IS 12 20 29.3 26.95 240.92 1.21 0.13 0.05 0.92<br />

C19 14 20 30.2 27.68 263.39 1.23 0.11 0.06 0.91<br />

WFS: wire feed speed [m/min]<br />

SO: stand-off [mm]<br />

Vut: set-up welding voltage [volts]<br />

V,.,: measured run average of welding voltage [volts]<br />

I ean: measured run average of welding current [Amps]<br />

TSI, TI, DCI, PR: measured run average of monitoring indices<br />

A considerable improvement has been observed with the adjusted set-up<br />

voltage. However, some of the conditions in dip transfer were still very spattery. A<br />

comparison between the levels of average. and maximum welding current produced by<br />

the BDH320 [ref. 51] and the BDH550, for the same welding parameters (V,.,, WFS,<br />

SO and Sw), reveals that the BDH550 delivers higher levels of average current (see<br />

Figure 6.2) and maximum current in the dip mode of metal transfer (see Figure 6.3).<br />

Since the level of spatter in the dip transfer mode is directly related to the maximum<br />

current reached during the short circuit (see section 2.1.5.2), the observed spatter<br />

levels could be explained by the higher current levels produced by the BDH550. In<br />

Figure 6.2, Imean_320 stands for the mean welding current produced by the BDH-<br />

320, Imean_550 stands for the mean welding current produced by the BDH-550 and<br />

Ipred stands for the mean welding current predicted using the equation 3.1. In Figure<br />

6.3, Imax_320 and Imax_550 stand for the maximum welding currents produced by<br />

the BDH-320 and BDH-550, respectively.<br />

128