LIBRARY ı6ıul 0) - Cranfield University

LIBRARY ı6ıul 0) - Cranfield University

LIBRARY ı6ıul 0) - Cranfield University

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

for selecting indirect weld parameters suitable to producing the required weld quality,<br />

as a response to the bead geometry information provided by sensors [refs. 11,178,<br />

179,180]. Although these controllers are reported to provide the parameter values<br />

that most likely suit the observed seam geometry, they essentially work in open loop.<br />

Closed-loop weld process control requires the observation of parameters that describe<br />

the current state of the process [ref. 178].<br />

Hunter et al. [ref. 168] used experimentally obtained steady state models to<br />

control gas metal arc welding. The authors [ref. 168] developed the control models by<br />

fitting to equation (2.37) the experimental data obtained from a factorial experiment,<br />

in which travel speed, wire feed speed, welding voltage and contact-tip-to-workpiece<br />

distance were used as the process inputs and the geometry of a flat position fillet<br />

weld, as the output. The authors [ref. 168] combined the resulting models in a matrix<br />

form in order to realise a multivariable controller for the gas metal arc welding<br />

process.<br />

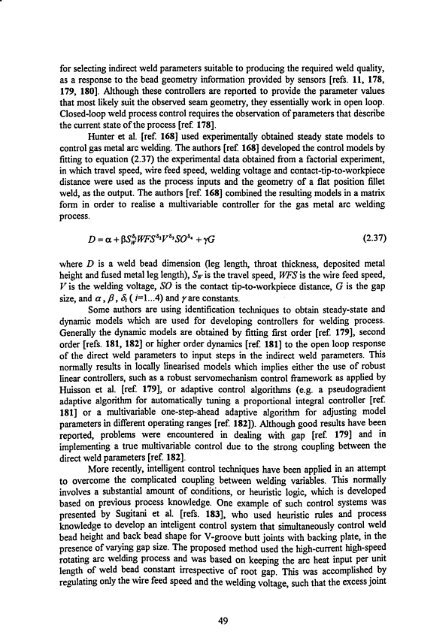

D= ac + 1SSWFS&2V83SO84<br />

+ yG<br />

(2.37)<br />

where D is a weld bead dimension (leg length, throat thickness, deposited metal<br />

height and fused metal leg length), SR-<br />

is the travel speed, WFS is the wire feed speed,<br />

V is the welding voltage, SO is the contact tip-to-workpiece distance, G is the gap<br />

size, and a, P, S; (i=1... 4) and y are constants.<br />

Some authors are using identification techniques to obtain steady-state and<br />

dynamic models which are used for developing controllers for welding process.<br />

Generally the dynamic models are obtained by fitting first order [ref. 179], second<br />

order [refs. 181,182] or higher order dynamics [ref. 181] to the open loop response<br />

of the direct weld parameters to input steps in the indirect weld parameters. This<br />

normally results in locally linearised models which implies either the use of robust<br />

linear controllers, such as a robust servomechanism control framework as applied by<br />

Huisson et al. [ref. 179], or adaptive control algorithms (e. g. a pseudogradient<br />

adaptive algorithm for automatically tuning a proportional integral controller [ref.<br />

181] or a multivariable one-step-ahead adaptive algorithm for adjusting model<br />

parameters in different operating ranges [ref. 182]). Although good results have been<br />

reported, problems were encountered in dealing with gap [ref. 179] and in<br />

implementing a true multivariable control due to the strong coupling between the<br />

direct weld parameters [ref. 182].<br />

More recently, intelligent control techniques have been applied in an attempt<br />

to overcome the complicated coupling between welding variables. This normally<br />

involves a substantial amount of conditions, or heuristic logic, which is developed<br />

based on previous process knowledge. One example of such control systems was<br />

presented by Sugitani et al. [refs. 183], who used heuristic rules and process<br />

knowledge to develop an inteligent control system that simultaneously control weld<br />

bead height and back bead shape for V-groove butt joints with backing plate, in the<br />

presence of varying gap size. The proposed method used the high-current high-speed<br />

rotating arc welding process and was based on keeping the arc heat input per unit<br />

length of weld bead constant irrespective of root gap. This was accomplished by<br />

regulating only the wire feed speed and the welding voltage, such that the excess joint<br />

49