LIBRARY ı6ıul 0) - Cranfield University

LIBRARY ı6ıul 0) - Cranfield University

LIBRARY ı6ıul 0) - Cranfield University

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

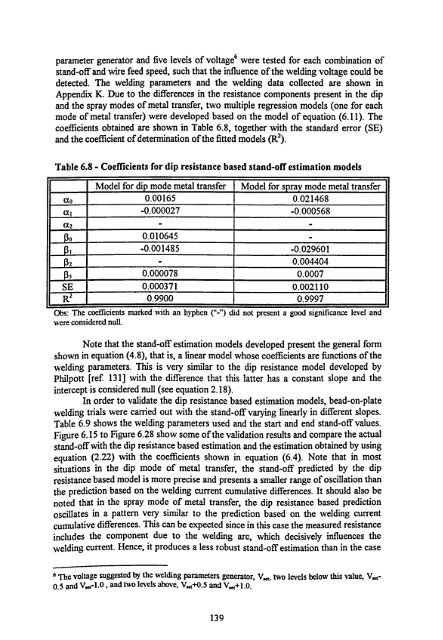

parameter generator and five levels of voltage" were tested for each combination of<br />

stand-off and wire feed speed, such that the influence of the welding voltage could be<br />

detected. The welding parameters and the welding data collected are shown in<br />

Appendix K. Due to the differences in the resistance components present in the dip<br />

and the spray modes of metal transfer, two multiple regression models (one for each<br />

mode of metal transfer) were developed based on the model of equation (6.11). The<br />

coefficients obtained are shown in Table 6.8, together with the standard error (SE)<br />

and the coefficient of determination of the fitted models (R2).<br />

Table 6.8 - Coefficients for dip resistance based stand-off estimation models<br />

Model for dip mode metal transfer Model for spray mode metal transfer<br />

0.00165 0.021468<br />

al -0.000027 -0.000568<br />

a2 - -<br />

0<br />

0.010645<br />

1 -0.001485 -0.029601<br />

2 - 0.004404<br />

3<br />

0.000078 0.0007<br />

SE 0.000371 0.002110<br />

R2 0.9900 0.9997<br />

Obs: The coefficients marked with an hyphen ("=) did not present a good significance level and<br />

were considered null.<br />

Note that the stand-off estimation models developed present the general form<br />

shown in equation (4.8), that is, a linear model whose coefficients are functions of the<br />

welding parameters. This is very similar to the dip resistance model developed by<br />

Philpott [ref. 131] with the difference that this latter has a constant slope and the<br />

intercept is considered null (see equation 2.18).<br />

In order to validate the dip resistance based estimation models, bead-on-plate<br />

welding trials were carried out with the stand-off varying linearly in different slopes.<br />

Table 6.9 shows the welding parameters used and the start and end stand-off values.<br />

Figure 6.15 to Figure 6.28 show some of the validation results and compare the actual<br />

stand-off with the dip resistance based estimation and the estimation obtained by using<br />

equation (2.22) with the coefficients shown in equation (6.4). Note that in most<br />

situations in the dip mode of metal transfer, the stand-off predicted by the dip<br />

resistance based model is more precise and presents a smaller range of oscillation than<br />

the prediction based on the welding current cumulative differences. It should also be<br />

noted that in the spray mode of metal transfer, the dip resistance based prediction<br />

oscillates in a pattern very similar to the prediction based on the welding current<br />

cumulative differences. This can be expected since in this case the measured resistance<br />

includes the component due to the welding arc, which decisively influences the<br />

welding current. Hence, it produces a less robust stand-off estimation than in the case<br />

6 The voltage suggested by the welding parameters generator, V,., two levels below this value, V. 4-<br />

0.5 and V e-1.0 , and two levels above, V, a+0.5 and V,, +1.0.<br />

139<br />

-