User's Manual AXF Magnetic Flowmeter Integral ... - Yokogawa

User's Manual AXF Magnetic Flowmeter Integral ... - Yokogawa

User's Manual AXF Magnetic Flowmeter Integral ... - Yokogawa

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

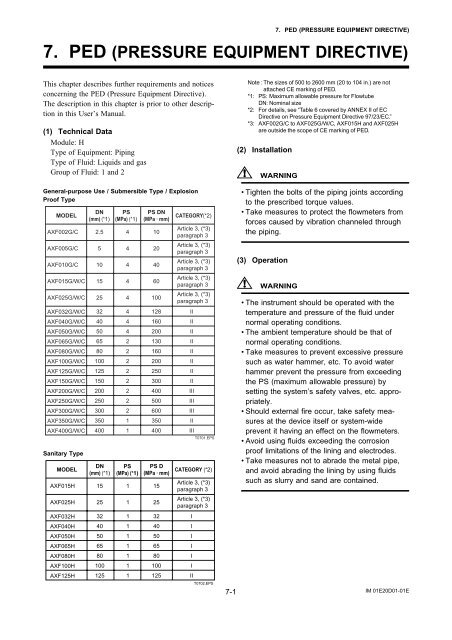

7. PED (PRESSURE EQUIPMENT DIRECTIVE)<br />

7. PED (PRESSURE EQUIPMENT DIRECTIVE)<br />

This chapter describes further requirements and notices<br />

concerning the PED (Pressure Equipment Directive).<br />

The description in this chapter is prior to other description<br />

in this User’s <strong>Manual</strong>.<br />

(1) Technical Data<br />

Module: H<br />

Type of Equipment: Piping<br />

Type of Fluid: Liquids and gas<br />

Group of Fluid: 1 and 2<br />

General-purpose Use / Submersible Type / Explosion<br />

Proof Type<br />

MODEL<br />

DN<br />

(mm) (*1)<br />

PS<br />

(MPa) (*1)<br />

PS DN<br />

(MPa · mm)<br />

<strong>AXF</strong>002G/C 2.5 4 10<br />

<strong>AXF</strong>005G/C 5 4 20<br />

<strong>AXF</strong>010G/C 10 4 40<br />

<strong>AXF</strong>015G/W/C 15 4 60<br />

<strong>AXF</strong>025G/W/C 25 4 100<br />

<strong>AXF</strong>032G/W/C<br />

<strong>AXF</strong>040G/W/C<br />

<strong>AXF</strong>050G/W/C<br />

<strong>AXF</strong>065G/W/C<br />

<strong>AXF</strong>080G/W/C<br />

<strong>AXF</strong>100G/W/C<br />

<strong>AXF</strong>125G/W/C<br />

<strong>AXF</strong>150G/W/C<br />

<strong>AXF</strong>200G/W/C<br />

<strong>AXF</strong>250G/W/C<br />

<strong>AXF</strong>300G/W/C<br />

<strong>AXF</strong>350G/W/C<br />

<strong>AXF</strong>400G/W/C<br />

Sanitary Type<br />

MODEL<br />

32<br />

40<br />

50<br />

65<br />

80<br />

100<br />

125<br />

150<br />

200<br />

250<br />

300<br />

350<br />

400<br />

DN<br />

(mm) (*1)<br />

4<br />

4<br />

4<br />

2<br />

2<br />

2<br />

2<br />

2<br />

2<br />

2<br />

2<br />

1<br />

1<br />

PS<br />

(MPa) (*1)<br />

128<br />

160<br />

200<br />

130<br />

160<br />

200<br />

250<br />

300<br />

400<br />

500<br />

600<br />

350<br />

400<br />

PS D<br />

(MPa · mm)<br />

<strong>AXF</strong>015H 15 1 15<br />

<strong>AXF</strong>025H 25 1 25<br />

<strong>AXF</strong>032H<br />

<strong>AXF</strong>040H<br />

<strong>AXF</strong>050H<br />

<strong>AXF</strong>065H<br />

<strong>AXF</strong>080H<br />

<strong>AXF</strong>100H<br />

<strong>AXF</strong>125H<br />

32<br />

40<br />

50<br />

65<br />

80<br />

100<br />

125<br />

1<br />

1<br />

1<br />

1<br />

1<br />

1<br />

1<br />

32<br />

40<br />

50<br />

65<br />

80<br />

100<br />

125<br />

CATEGORY(*2)<br />

Article 3, (*3)<br />

paragraph 3<br />

Article 3, (*3)<br />

paragraph 3<br />

Article 3, (*3)<br />

paragraph 3<br />

Article 3, (*3)<br />

paragraph 3<br />

Article 3, (*3)<br />

paragraph 3<br />

II<br />

II<br />

II<br />

II<br />

II<br />

II<br />

II<br />

II<br />

III<br />

III<br />

III<br />

II<br />

III<br />

T0701.EPS<br />

CATEGORY (*2)<br />

Article 3, (*3)<br />

paragraph 3<br />

Article 3, (*3)<br />

paragraph 3<br />

I<br />

I<br />

I<br />

I<br />

I<br />

I<br />

II<br />

T0702.EPS<br />

7-1<br />

Note : The sizes of 500 to 2600 mm (20 to 104 in.) are not<br />

attached CE marking of PED.<br />

*1: PS: Maximum allowable pressure for Flowtube<br />

DN: Nominal size<br />

*2: For details, see “Table 6 covered by ANNEX II of EC<br />

Directive on Pressure Equipment Directive 97/23/EC.”<br />

*3: <strong>AXF</strong>002G/C to <strong>AXF</strong>025G/W/C, <strong>AXF</strong>015H and <strong>AXF</strong>025H<br />

are outside the scope of CE marking of PED.<br />

(2) Installation<br />

WARNING<br />

• Tighten the bolts of the piping joints according<br />

to the prescribed torque values.<br />

• Take measures to protect the flowmeters from<br />

forces caused by vibration channeled through<br />

the piping.<br />

(3) Operation<br />

WARNING<br />

• The instrument should be operated with the<br />

temperature and pressure of the fluid under<br />

normal operating conditions.<br />

• The ambient temperature should be that of<br />

normal operating conditions.<br />

• Take measures to prevent excessive pressure<br />

such as water hammer, etc. To avoid water<br />

hammer prevent the pressure from exceeding<br />

the PS (maximum allowable pressure) by<br />

setting the system’s safety valves, etc. appropriately.<br />

• Should external fire occur, take safety measures<br />

at the device itself or system-wide<br />

prevent it having an effect on the flowmeters.<br />

• Avoid using fluids exceeding the corrosion<br />

proof limitations of the lining and electrodes.<br />

• Take measures not to abrade the metal pipe,<br />

and avoid abrading the lining by using fluids<br />

such as slurry and sand are contained.<br />

IM 01E20D01-01E