User's Manual AXF Magnetic Flowmeter Integral ... - Yokogawa

User's Manual AXF Magnetic Flowmeter Integral ... - Yokogawa

User's Manual AXF Magnetic Flowmeter Integral ... - Yokogawa

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

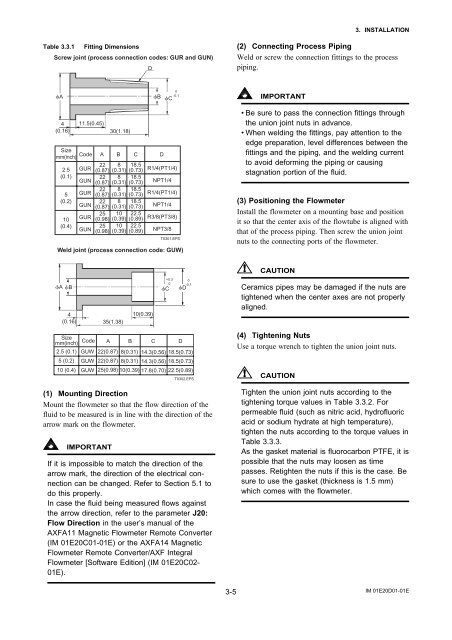

3. INSTALLATION<br />

Table 3.3.1 Fitting Dimensions<br />

Screw joint (process connection codes: GUR and GUN)<br />

D<br />

(2) Connecting Process Piping<br />

Weld or screw the connection fittings to the process<br />

piping.<br />

A<br />

B C<br />

0<br />

-0.1<br />

IMPORTANT<br />

4<br />

(0.16)<br />

Size<br />

mm(inch) Code A B C D<br />

2.5<br />

(0.1)<br />

5<br />

(0.2)<br />

10<br />

(0.4)<br />

11.5(0.45)<br />

GUR<br />

GUN<br />

GUR<br />

GUN<br />

GUR<br />

GUN<br />

22<br />

(0.87)<br />

22<br />

(0.87)<br />

22<br />

(0.87)<br />

22<br />

(0.87)<br />

25<br />

(0.98)<br />

25<br />

(0.98)<br />

30(1.18)<br />

8<br />

(0.31)<br />

8<br />

(0.31)<br />

8<br />

(0.31)<br />

8<br />

(0.31)<br />

10<br />

(0.39)<br />

10<br />

(0.39)<br />

18.5<br />

(0.73)<br />

18.5<br />

(0.73)<br />

18.5<br />

(0.73)<br />

18.5<br />

(0.73)<br />

22.5<br />

(0.89)<br />

22.5<br />

(0.89)<br />

R1/4(PT1/4)<br />

NPT1/4<br />

R1/4(PT1/4)<br />

NPT1/4<br />

R3/8(PT3/8)<br />

NPT3/8<br />

T0301.EPS<br />

Weld joint (process connection code: GUW)<br />

•Be sure to pass the connection fittings through<br />

the union joint nuts in advance.<br />

•When welding the fittings, pay attention to the<br />

edge preparation, level differences between the<br />

fittings and the piping, and the welding current<br />

to avoid deforming the piping or causing<br />

stagnation portion of the fluid.<br />

(3) Positioning the <strong>Flowmeter</strong><br />

Install the flowmeter on a mounting base and position<br />

it so that the center axis of the flowtube is aligned with<br />

that of the process piping. Then screw the union joint<br />

nuts to the connecting ports of the flowmeter.<br />

CAUTION<br />

A B<br />

4<br />

(0.16) 35(1.38)<br />

10(0.39)<br />

C<br />

+0.3<br />

0<br />

D<br />

0<br />

-0.1<br />

Ceramics pipes may be damaged if the nuts are<br />

tightened when the center axes are not properly<br />

aligned.<br />

Size<br />

mm(inch)<br />

Code<br />

2.5 (0.1) GUW<br />

5 (0.2) GUW<br />

10 (0.4) GUW<br />

A B C D<br />

22(0.87) 8(0.31) 14.3(0.56) 18.5(0.73)<br />

22(0.87) 8(0.31) 14.3(0.56) 18.5(0.73)<br />

25(0.98) 10(0.39) 17.8(0.70) 22.5(0.89)<br />

T0302.EPS<br />

(1) Mounting Direction<br />

Mount the flowmeter so that the flow direction of the<br />

fluid to be measured is in line with the direction of the<br />

arrow mark on the flowmeter.<br />

IMPORTANT<br />

If it is impossible to match the direction of the<br />

arrow mark, the direction of the electrical connection<br />

can be changed. Refer to Section 5.1 to<br />

do this properly.<br />

In case the fluid being measured flows against<br />

the arrow direction, refer to the parameter J20:<br />

Flow Direction in the user’s manual of the<br />

<strong>AXF</strong>A11 <strong>Magnetic</strong> <strong>Flowmeter</strong> Remote Converter<br />

(IM 01E20C01-01E) or the <strong>AXF</strong>A14 <strong>Magnetic</strong><br />

<strong>Flowmeter</strong> Remote Converter/<strong>AXF</strong> <strong>Integral</strong><br />

<strong>Flowmeter</strong> [Software Edition] (IM 01E20C02-<br />

01E).<br />

(4) Tightening Nuts<br />

Use a torque wrench to tighten the union joint nuts.<br />

CAUTION<br />

Tighten the union joint nuts according to the<br />

tightening torque values in Table 3.3.2. For<br />

permeable fluid (such as nitric acid, hydrofluoric<br />

acid or sodium hydrate at high temperature),<br />

tighten the nuts according to the torque values in<br />

Table 3.3.3.<br />

As the gasket material is fluorocarbon PTFE, it is<br />

possible that the nuts may loosen as time<br />

passes. Retighten the nuts if this is the case. Be<br />

sure to use the gasket (thickness is 1.5 mm)<br />

which comes with the flowmeter.<br />

3-5<br />

IM 01E20D01-01E