Experimental and Numerical Analysis of a PCM-Supported ...

Experimental and Numerical Analysis of a PCM-Supported ...

Experimental and Numerical Analysis of a PCM-Supported ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

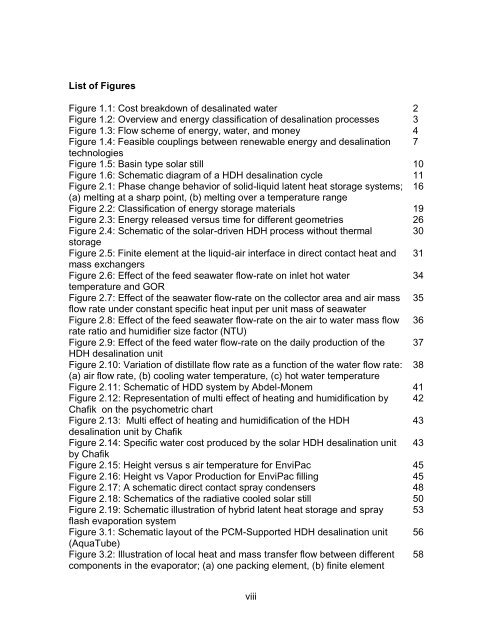

List <strong>of</strong> Figures<br />

Figure 1.1: Cost breakdown <strong>of</strong> desalinated water 2<br />

Figure 1.2: Overview <strong>and</strong> energy classification <strong>of</strong> desalination processes 3<br />

Figure 1.3: Flow scheme <strong>of</strong> energy, water, <strong>and</strong> money 4<br />

Figure 1.4: Feasible couplings between renewable energy <strong>and</strong> desalination 7<br />

technologies<br />

Figure 1.5: Basin type solar still 10<br />

Figure 1.6: Schematic diagram <strong>of</strong> a HDH desalination cycle 11<br />

Figure 2.1: Phase change behavior <strong>of</strong> solid-liquid latent heat storage systems; 16<br />

(a) melting at a sharp point, (b) melting over a temperature range<br />

Figure 2.2: Classification <strong>of</strong> energy storage materials 19<br />

Figure 2.3: Energy released versus time for different geometries 26<br />

Figure 2.4: Schematic <strong>of</strong> the solar-driven HDH process without thermal 30<br />

storage<br />

Figure 2.5: Finite element at the liquid-air interface in direct contact heat <strong>and</strong> 31<br />

mass exchangers<br />

Figure 2.6: Effect <strong>of</strong> the feed seawater flow-rate on inlet hot water<br />

34<br />

temperature <strong>and</strong> GOR<br />

Figure 2.7: Effect <strong>of</strong> the seawater flow-rate on the collector area <strong>and</strong> air mass 35<br />

flow rate under constant specific heat input per unit mass <strong>of</strong> seawater<br />

Figure 2.8: Effect <strong>of</strong> the feed seawater flow-rate on the air to water mass flow 36<br />

rate ratio <strong>and</strong> humidifier size factor (NTU)<br />

Figure 2.9: Effect <strong>of</strong> the feed water flow-rate on the daily production <strong>of</strong> the 37<br />

HDH desalination unit<br />

Figure 2.10: Variation <strong>of</strong> distillate flow rate as a function <strong>of</strong> the water flow rate: 38<br />

(a) air flow rate, (b) cooling water temperature, (c) hot water temperature<br />

Figure 2.11: Schematic <strong>of</strong> HDD system by Abdel-Monem 41<br />

Figure 2.12: Representation <strong>of</strong> multi effect <strong>of</strong> heating <strong>and</strong> humidification by 42<br />

Chafik on the psychometric chart<br />

Figure 2.13: Multi effect <strong>of</strong> heating <strong>and</strong> humidification <strong>of</strong> the HDH<br />

43<br />

desalination unit by Chafik<br />

Figure 2.14: Specific water cost produced by the solar HDH desalination unit 43<br />

by Chafik<br />

Figure 2.15: Height versus s air temperature for EnviPac 45<br />

Figure 2.16: Height vs Vapor Production for EnviPac filling 45<br />

Figure 2.17: A schematic direct contact spray condensers 48<br />

Figure 2.18: Schematics <strong>of</strong> the radiative cooled solar still 50<br />

Figure 2.19: Schematic illustration <strong>of</strong> hybrid latent heat storage <strong>and</strong> spray 53<br />

flash evaporation system<br />

Figure 3.1: Schematic layout <strong>of</strong> the <strong>PCM</strong>-<strong>Supported</strong> HDH desalination unit 56<br />

(AquaTube)<br />

Figure 3.2: Illustration <strong>of</strong> local heat <strong>and</strong> mass transfer flow between different 58<br />

components in the evaporator; (a) one packing element, (b) finite element<br />

viii