Experimental and Numerical Analysis of a PCM-Supported ...

Experimental and Numerical Analysis of a PCM-Supported ...

Experimental and Numerical Analysis of a PCM-Supported ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

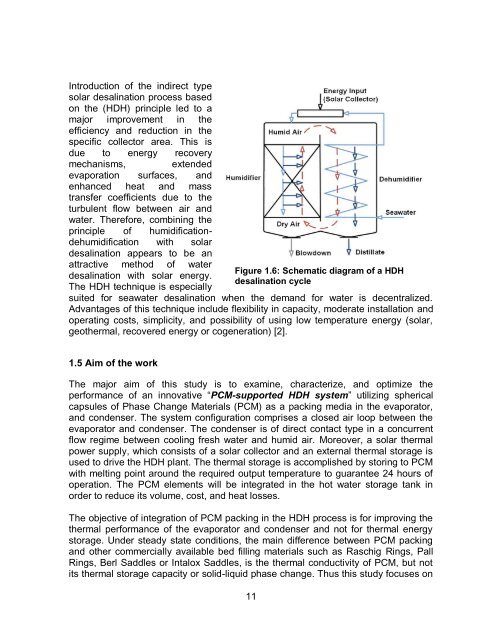

Introduction <strong>of</strong> the indirect type<br />

solar desalination process based<br />

on the (HDH) principle led to a<br />

major improvement in the<br />

efficiency <strong>and</strong> reduction in the<br />

specific collector area. This is<br />

due to energy recovery<br />

mechanisms, extended<br />

evaporation surfaces, <strong>and</strong><br />

enhanced heat <strong>and</strong> mass<br />

transfer coefficients due to the<br />

turbulent flow between air <strong>and</strong><br />

water. Therefore, combining the<br />

principle <strong>of</strong> humidificationdehumidification<br />

with solar<br />

desalination appears to be an<br />

attractive method <strong>of</strong> water<br />

desalination with solar energy.<br />

The HDH technique is especially<br />

Figure 1.6: Schematic diagram <strong>of</strong> a HDH<br />

desalination cycle<br />

suited for seawater desalination when the dem<strong>and</strong> for water is decentralized.<br />

Advantages <strong>of</strong> this technique include flexibility in capacity, moderate installation <strong>and</strong><br />

operating costs, simplicity, <strong>and</strong> possibility <strong>of</strong> using low temperature energy (solar,<br />

geothermal, recovered energy or cogeneration) [2].<br />

1.5 Aim <strong>of</strong> the work<br />

The major aim <strong>of</strong> this study is to examine, characterize, <strong>and</strong> optimize the<br />

performance <strong>of</strong> an innovative “<strong>PCM</strong>-supported HDH system” utilizing spherical<br />

capsules <strong>of</strong> Phase Change Materials (<strong>PCM</strong>) as a packing media in the evaporator,<br />

<strong>and</strong> condenser. The system configuration comprises a closed air loop between the<br />

evaporator <strong>and</strong> condenser. The condenser is <strong>of</strong> direct contact type in a concurrent<br />

flow regime between cooling fresh water <strong>and</strong> humid air. Moreover, a solar thermal<br />

power supply, which consists <strong>of</strong> a solar collector <strong>and</strong> an external thermal storage is<br />

used to drive the HDH plant. The thermal storage is accomplished by storing to <strong>PCM</strong><br />

with melting point around the required output temperature to guarantee 24 hours <strong>of</strong><br />

operation. The <strong>PCM</strong> elements will be integrated in the hot water storage tank in<br />

order to reduce its volume, cost, <strong>and</strong> heat losses.<br />

The objective <strong>of</strong> integration <strong>of</strong> <strong>PCM</strong> packing in the HDH process is for improving the<br />

thermal performance <strong>of</strong> the evaporator <strong>and</strong> condenser <strong>and</strong> not for thermal energy<br />

storage. Under steady state conditions, the main difference between <strong>PCM</strong> packing<br />

<strong>and</strong> other commercially available bed filling materials such as Raschig Rings, Pall<br />

Rings, Berl Saddles or Intalox Saddles, is the thermal conductivity <strong>of</strong> <strong>PCM</strong>, but not<br />

its thermal storage capacity or solid-liquid phase change. Thus this study focuses on<br />

11