Experimental and Numerical Analysis of a PCM-Supported ...

Experimental and Numerical Analysis of a PCM-Supported ...

Experimental and Numerical Analysis of a PCM-Supported ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

performance <strong>and</strong> its threshold value shouldn’t exceed unity. Realistic units would<br />

include an energy recovery system for lower energy consumption, as was described<br />

in the previous chapters, <strong>and</strong> will be investigated numerically in chapter 8 when<br />

considering the complete solar driven HDH plant.<br />

5.5.1 Behavior <strong>of</strong> the <strong>PCM</strong>-supported HDH cycle<br />

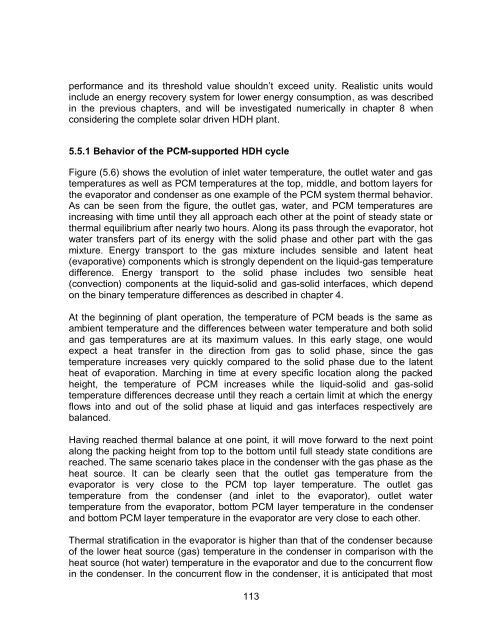

Figure (5.6) shows the evolution <strong>of</strong> inlet water temperature, the outlet water <strong>and</strong> gas<br />

temperatures as well as <strong>PCM</strong> temperatures at the top, middle, <strong>and</strong> bottom layers for<br />

the evaporator <strong>and</strong> condenser as one example <strong>of</strong> the <strong>PCM</strong> system thermal behavior.<br />

As can be seen from the figure, the outlet gas, water, <strong>and</strong> <strong>PCM</strong> temperatures are<br />

increasing with time until they all approach each other at the point <strong>of</strong> steady state or<br />

thermal equilibrium after nearly two hours. Along its pass through the evaporator, hot<br />

water transfers part <strong>of</strong> its energy with the solid phase <strong>and</strong> other part with the gas<br />

mixture. Energy transport to the gas mixture includes sensible <strong>and</strong> latent heat<br />

(evaporative) components which is strongly dependent on the liquid-gas temperature<br />

difference. Energy transport to the solid phase includes two sensible heat<br />

(convection) components at the liquid-solid <strong>and</strong> gas-solid interfaces, which depend<br />

on the binary temperature differences as described in chapter 4.<br />

At the beginning <strong>of</strong> plant operation, the temperature <strong>of</strong> <strong>PCM</strong> beads is the same as<br />

ambient temperature <strong>and</strong> the differences between water temperature <strong>and</strong> both solid<br />

<strong>and</strong> gas temperatures are at its maximum values. In this early stage, one would<br />

expect a heat transfer in the direction from gas to solid phase, since the gas<br />

temperature increases very quickly compared to the solid phase due to the latent<br />

heat <strong>of</strong> evaporation. Marching in time at every specific location along the packed<br />

height, the temperature <strong>of</strong> <strong>PCM</strong> increases while the liquid-solid <strong>and</strong> gas-solid<br />

temperature differences decrease until they reach a certain limit at which the energy<br />

flows into <strong>and</strong> out <strong>of</strong> the solid phase at liquid <strong>and</strong> gas interfaces respectively are<br />

balanced.<br />

Having reached thermal balance at one point, it will move forward to the next point<br />

along the packing height from top to the bottom until full steady state conditions are<br />

reached. The same scenario takes place in the condenser with the gas phase as the<br />

heat source. It can be clearly seen that the outlet gas temperature from the<br />

evaporator is very close to the <strong>PCM</strong> top layer temperature. The outlet gas<br />

temperature from the condenser (<strong>and</strong> inlet to the evaporator), outlet water<br />

temperature from the evaporator, bottom <strong>PCM</strong> layer temperature in the condenser<br />

<strong>and</strong> bottom <strong>PCM</strong> layer temperature in the evaporator are very close to each other.<br />

Thermal stratification in the evaporator is higher than that <strong>of</strong> the condenser because<br />

<strong>of</strong> the lower heat source (gas) temperature in the condenser in comparison with the<br />

heat source (hot water) temperature in the evaporator <strong>and</strong> due to the concurrent flow<br />

in the condenser. In the concurrent flow in the condenser, it is anticipated that most<br />

113