Experimental and Numerical Analysis of a PCM-Supported ...

Experimental and Numerical Analysis of a PCM-Supported ...

Experimental and Numerical Analysis of a PCM-Supported ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>of</strong> the condensation takes place in the first top layers <strong>of</strong> the bed where the cooling<br />

water temperature is at its lowest level while the gas temperature is at its maximum<br />

level. Hence, the water temperature increases downwards due to condensation <strong>and</strong><br />

cooling <strong>of</strong> humid air. This causes the temperature <strong>of</strong> the middle <strong>PCM</strong> layer to be<br />

higher than that at the top layer, as depicted in figure (5.6b), due to absorption <strong>of</strong> a<br />

large portion <strong>of</strong> the latent heat <strong>of</strong> condensation by the middle <strong>PCM</strong> layer. The middle<br />

<strong>PCM</strong> layer reaches steady state conditions earlier than <strong>PCM</strong> layers at top <strong>and</strong><br />

bottom <strong>of</strong> the condenser, since the middle layer acts as a thermal buffer before the<br />

bottom layer. While the inlet <strong>and</strong> outlet gas temperatures approaching steady state<br />

conditions, the inlet cooling water temperature was gradually increasing over time<br />

during this experiment, which causes the retardation <strong>of</strong> the top <strong>PCM</strong> layer to reach<br />

steady state. However, it can be seen in figure (5.6) that the intermediate <strong>PCM</strong> layer<br />

temperature lies between both inlet <strong>and</strong> outlet gas temperatures in both components<br />

under the specified boundary conditions.<br />

Figure (5.7) shows the evolution <strong>of</strong> water <strong>and</strong> gas temperatures at top <strong>and</strong> bottom <strong>of</strong><br />

the empty spheres packing unit. It can be seen that the Non-<strong>PCM</strong> system achieves<br />

steady state sooner than the <strong>PCM</strong> based one. This is self-evident due to the fact that<br />

the hollow plastic spheres have a negligible thermal storage capacity compared to<br />

<strong>PCM</strong> spheres. The plots on figure (5.8) <strong>and</strong> table (5.3) illustrate that the differences<br />

between inlet <strong>and</strong> outlet gas <strong>and</strong> inlet <strong>and</strong> outlet liquid temperatures in the<br />

evaporator <strong>and</strong> condenser <strong>of</strong> the <strong>PCM</strong> packing are higher than those <strong>of</strong> the Empty<br />

spheres packing.<br />

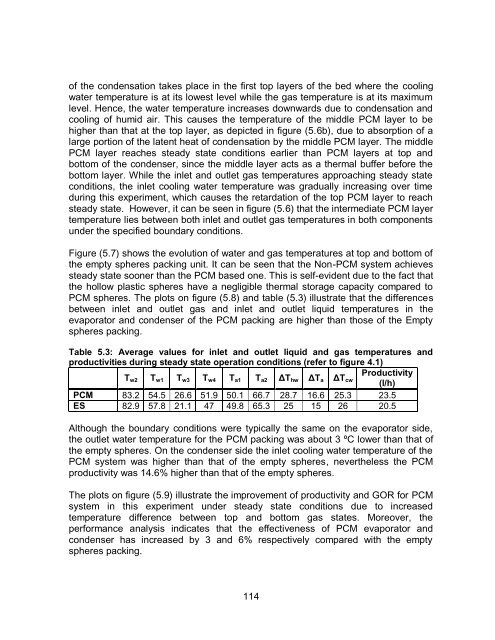

Table 5.3: Average values for inlet <strong>and</strong> outlet liquid <strong>and</strong> gas temperatures <strong>and</strong><br />

productivities during steady state operation conditions (refer to figure 4.1)<br />

Productivity<br />

T w2 T w1 T w3 T w4 T a1 T a2 ΔT hw ΔT a ΔT cw<br />

(l/h)<br />

<strong>PCM</strong> 83.2 54.5 26.6 51.9 50.1 66.7 28.7 16.6 25.3 23.5<br />

ES 82.9 57.8 21.1 47 49.8 65.3 25 15 26 20.5<br />

Although the boundary conditions were typically the same on the evaporator side,<br />

the outlet water temperature for the <strong>PCM</strong> packing was about 3 ºC lower than that <strong>of</strong><br />

the empty spheres. On the condenser side the inlet cooling water temperature <strong>of</strong> the<br />

<strong>PCM</strong> system was higher than that <strong>of</strong> the empty spheres, nevertheless the <strong>PCM</strong><br />

productivity was 14.6% higher than that <strong>of</strong> the empty spheres.<br />

The plots on figure (5.9) illustrate the improvement <strong>of</strong> productivity <strong>and</strong> GOR for <strong>PCM</strong><br />

system in this experiment under steady state conditions due to increased<br />

temperature difference between top <strong>and</strong> bottom gas states. Moreover, the<br />

performance analysis indicates that the effectiveness <strong>of</strong> <strong>PCM</strong> evaporator <strong>and</strong><br />

condenser has increased by 3 <strong>and</strong> 6% respectively compared with the empty<br />

spheres packing.<br />

114