Experimental and Numerical Analysis of a PCM-Supported ...

Experimental and Numerical Analysis of a PCM-Supported ...

Experimental and Numerical Analysis of a PCM-Supported ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

temperature is at its maximum level, <strong>and</strong> moves downwards due to stratification <strong>of</strong><br />

both liquid <strong>and</strong> gas phases as well as the low effective thermal conductivity <strong>of</strong> <strong>PCM</strong><br />

along the packing height. Thereafter, a sensible heat component increases the <strong>PCM</strong><br />

temperature until reaching the steady state conditions. Since the melting front moves<br />

in time downward in the bed, this looks like propagating waves or a “sea snake”<br />

rising up from the bottom. Little peaks <strong>of</strong> temperatures above the melting range can<br />

be observed near the top <strong>of</strong> the bed, these may represent some locations just<br />

around the breakeven points during the transient period with the gas phase<br />

temperature pr<strong>of</strong>ile (reference is made to figure 5.4), <strong>and</strong> perhaps also due to<br />

melting <strong>of</strong> <strong>PCM</strong> over a mushy region rather than a sharp melting front.<br />

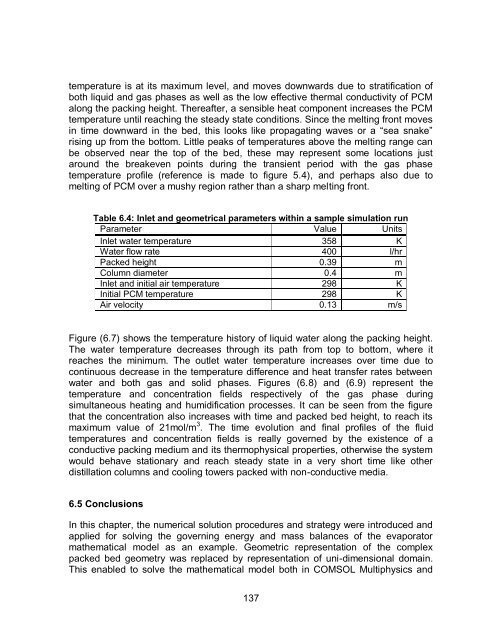

Table 6.4: Inlet <strong>and</strong> geometrical parameters within a sample simulation run<br />

Parameter Value Units<br />

Inlet water temperature 358 K<br />

Water flow rate 400 l/hr<br />

Packed height 0.39 m<br />

Column diameter 0.4 m<br />

Inlet <strong>and</strong> initial air temperature 298 K<br />

Initial <strong>PCM</strong> temperature 298 K<br />

Air velocity 0.13 m/s<br />

Figure (6.7) shows the temperature history <strong>of</strong> liquid water along the packing height.<br />

The water temperature decreases through its path from top to bottom, where it<br />

reaches the minimum. The outlet water temperature increases over time due to<br />

continuous decrease in the temperature difference <strong>and</strong> heat transfer rates between<br />

water <strong>and</strong> both gas <strong>and</strong> solid phases. Figures (6.8) <strong>and</strong> (6.9) represent the<br />

temperature <strong>and</strong> concentration fields respectively <strong>of</strong> the gas phase during<br />

simultaneous heating <strong>and</strong> humidification processes. It can be seen from the figure<br />

that the concentration also increases with time <strong>and</strong> packed bed height, to reach its<br />

maximum value <strong>of</strong> 21mol/m 3 . The time evolution <strong>and</strong> final pr<strong>of</strong>iles <strong>of</strong> the fluid<br />

temperatures <strong>and</strong> concentration fields is really governed by the existence <strong>of</strong> a<br />

conductive packing medium <strong>and</strong> its thermophysical properties, otherwise the system<br />

would behave stationary <strong>and</strong> reach steady state in a very short time like other<br />

distillation columns <strong>and</strong> cooling towers packed with non-conductive media.<br />

6.5 Conclusions<br />

In this chapter, the numerical solution procedures <strong>and</strong> strategy were introduced <strong>and</strong><br />

applied for solving the governing energy <strong>and</strong> mass balances <strong>of</strong> the evaporator<br />

mathematical model as an example. Geometric representation <strong>of</strong> the complex<br />

packed bed geometry was replaced by representation <strong>of</strong> uni-dimensional domain.<br />

This enabled to solve the mathematical model both in COMSOL Multiphysics <strong>and</strong><br />

137