Experimental and Numerical Analysis of a PCM-Supported ...

Experimental and Numerical Analysis of a PCM-Supported ...

Experimental and Numerical Analysis of a PCM-Supported ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

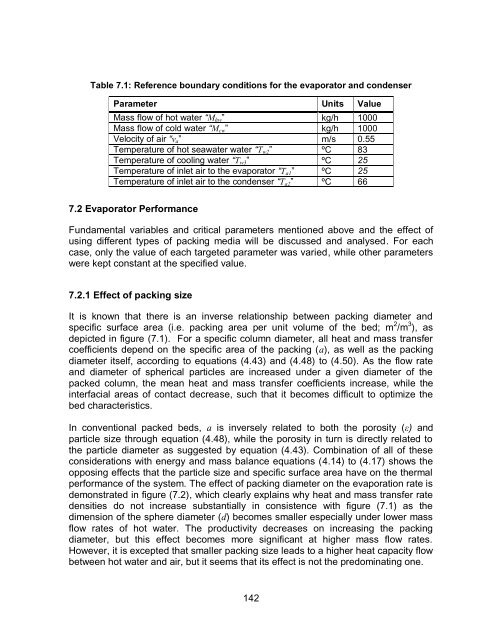

Table 7.1: Reference boundary conditions for the evaporator <strong>and</strong> condenser<br />

Parameter Units Value<br />

Mass flow <strong>of</strong> hot water “M hw ” kg/h 1000<br />

Mass flow <strong>of</strong> cold water “M cw ” kg/h 1000<br />

Velocity <strong>of</strong> air “v a ” m/s 0.55<br />

Temperature <strong>of</strong> hot seawater water “T w2 ” ºC 83<br />

Temperature <strong>of</strong> cooling water “T w3 ” ºC 25<br />

Temperature <strong>of</strong> inlet air to the evaporator “T a1 ” ºC 25<br />

Temperature <strong>of</strong> inlet air to the condenser “T a2 ” ºC 66<br />

7.2 Evaporator Performance<br />

Fundamental variables <strong>and</strong> critical parameters mentioned above <strong>and</strong> the effect <strong>of</strong><br />

using different types <strong>of</strong> packing media will be discussed <strong>and</strong> analysed. For each<br />

case, only the value <strong>of</strong> each targeted parameter was varied, while other parameters<br />

were kept constant at the specified value.<br />

7.2.1 Effect <strong>of</strong> packing size<br />

It is known that there is an inverse relationship between packing diameter <strong>and</strong><br />

specific surface area (i.e. packing area per unit volume <strong>of</strong> the bed; m 2 /m 3 ), as<br />

depicted in figure (7.1). For a specific column diameter, all heat <strong>and</strong> mass transfer<br />

coefficients depend on the specific area <strong>of</strong> the packing (a), as well as the packing<br />

diameter itself, according to equations (4.43) <strong>and</strong> (4.48) to (4.50). As the flow rate<br />

<strong>and</strong> diameter <strong>of</strong> spherical particles are increased under a given diameter <strong>of</strong> the<br />

packed column, the mean heat <strong>and</strong> mass transfer coefficients increase, while the<br />

interfacial areas <strong>of</strong> contact decrease, such that it becomes difficult to optimize the<br />

bed characteristics.<br />

In conventional packed beds, a is inversely related to both the porosity (ε) <strong>and</strong><br />

particle size through equation (4.48), while the porosity in turn is directly related to<br />

the particle diameter as suggested by equation (4.43). Combination <strong>of</strong> all <strong>of</strong> these<br />

considerations with energy <strong>and</strong> mass balance equations (4.14) to (4.17) shows the<br />

opposing effects that the particle size <strong>and</strong> specific surface area have on the thermal<br />

performance <strong>of</strong> the system. The effect <strong>of</strong> packing diameter on the evaporation rate is<br />

demonstrated in figure (7.2), which clearly explains why heat <strong>and</strong> mass transfer rate<br />

densities do not increase substantially in consistence with figure (7.1) as the<br />

dimension <strong>of</strong> the sphere diameter (d) becomes smaller especially under lower mass<br />

flow rates <strong>of</strong> hot water. The productivity decreases on increasing the packing<br />

diameter, but this effect becomes more significant at higher mass flow rates.<br />

However, it is excepted that smaller packing size leads to a higher heat capacity flow<br />

between hot water <strong>and</strong> air, but it seems that its effect is not the predominating one.<br />

142