Experimental and Numerical Analysis of a PCM-Supported ...

Experimental and Numerical Analysis of a PCM-Supported ...

Experimental and Numerical Analysis of a PCM-Supported ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

liquid <strong>and</strong> solid phases, respectively. At steady state conditions, the energy flow from<br />

gas to solid phase equilibrates with the energy flow from solid to liquid phase <strong>and</strong> the<br />

local temperatures <strong>of</strong> all phases remain constant. Any change <strong>of</strong> the system<br />

parameters will break steady state conditions, <strong>and</strong> the local temperatures will<br />

change.<br />

The condensation rate depends mainly on the vapor pressure gradient between the<br />

bulk gas phase from one side <strong>and</strong> both the gas-liquid interface <strong>and</strong> the gas-solid<br />

interface from the other side. The vapor pressure is a direct function <strong>of</strong> the<br />

respective local temperatures, assuming saturation conditions in closed loop cycles.<br />

However, the sensible energy flow components also affect the film temperature at<br />

gas-liquid interface <strong>and</strong> gas-solid interface, which indirectly affects the condensation<br />

rate. On the other h<strong>and</strong>, condensation contributes a considerable fraction <strong>of</strong> latent<br />

heat to the liquid <strong>and</strong> solid phases <strong>and</strong> leads to rising their temperatures, which in<br />

turn affects both heat <strong>and</strong> mass balances. In fact, the microscopic analysis <strong>of</strong> the<br />

condensation process is much more complicated than the described macroscopic<br />

analysis, while the later is sufficiently accurate for the present application <strong>and</strong> range<br />

<strong>of</strong> operation conditions in comparison with the experimental measurements as will<br />

be presented later.<br />

4.2.4 Closure relationships<br />

Predictive models for packed column performance incorporate macroscopic<br />

properties <strong>of</strong> the entire column based on volume or spatial averaging technique<br />

which was developed by Slattery [26], rather than focusing rigorously on underlying<br />

local variations <strong>of</strong> momentum, heat, <strong>and</strong> mass transfer processes. Hence, closure<br />

models have to be provided in the numerical scheme to capture the information that<br />

is lost in the averaging process. Careful selection <strong>of</strong> the appropriate closure<br />

relationships from literature is therefore a fundamental factor for achieving high<br />

accuracy <strong>of</strong> the simulation model. Modeling <strong>and</strong> design <strong>of</strong> a r<strong>and</strong>omly packed<br />

distillation column requires a reliable specification <strong>of</strong> effective interfacial areas,<br />

phase fractions, heat <strong>and</strong> mass transfer coefficients, <strong>and</strong> pressure drop. The next<br />

sections will be devoted to the adopted modeling procedures <strong>and</strong> calculations <strong>of</strong><br />

such critical parameters.<br />

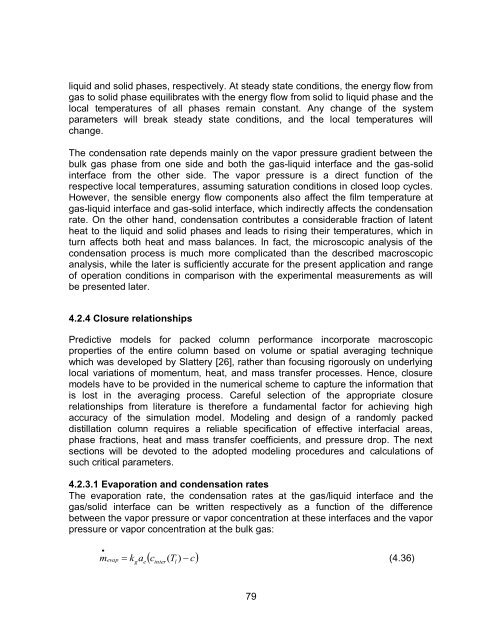

4.2.3.1 Evaporation <strong>and</strong> condensation rates<br />

The evaporation rate, the condensation rates at the gas/liquid interface <strong>and</strong> the<br />

gas/solid interface can be written respectively as a function <strong>of</strong> the difference<br />

between the vapor pressure or vapor concentration at these interfaces <strong>and</strong> the vapor<br />

pressure or vapor concentration at the bulk gas:<br />

<br />

m<br />

evap<br />

k<br />

g<br />

a<br />

e<br />

<br />

c<br />

inter<br />

<br />

( T ) c<br />

(4.36)<br />

l<br />

79