Experimental and Numerical Analysis of a PCM-Supported ...

Experimental and Numerical Analysis of a PCM-Supported ...

Experimental and Numerical Analysis of a PCM-Supported ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

to 550 kWh/m 3 <strong>of</strong> distilled water <strong>and</strong> 4 to 12 l/m 2 .day <strong>of</strong> solar collector area, as<br />

reported by Narayan et al [149].<br />

GOR is directly proportional to heat <strong>and</strong> mass transfer effectiveness in the<br />

evaporator <strong>and</strong> condenser or both the temperature drop <strong>of</strong> hot water in the<br />

evaporator (ΔT hw ) <strong>and</strong> temperature rise <strong>of</strong> feed seawater in the condenser (ΔT cw )<br />

<strong>and</strong> inversely to the temperature jump in the solar collector (ΔT coll ). When the HDH<br />

system works efficiently, both the temperature drop in the evaporator <strong>and</strong><br />

temperature rise through the condenser become high, which reduces the required<br />

temperature jump in the collector, i.e. the required energy input to produce same<br />

amount <strong>of</strong> distillate.<br />

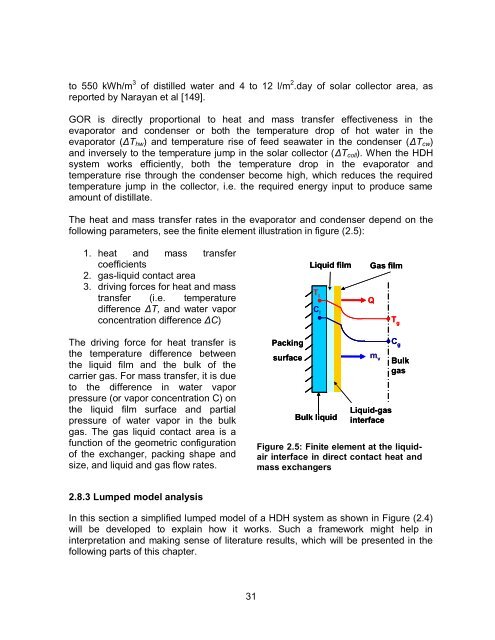

The heat <strong>and</strong> mass transfer rates in the evaporator <strong>and</strong> condenser depend on the<br />

following parameters, see the finite element illustration in figure (2.5):<br />

1. heat <strong>and</strong> mass transfer<br />

coefficients<br />

2. gas-liquid contact area<br />

3. driving forces for heat <strong>and</strong> mass<br />

transfer (i.e. temperature<br />

difference ΔT, <strong>and</strong> water vapor<br />

concentration difference ΔC)<br />

Liquid film<br />

T l<br />

C l<br />

Gas film<br />

Q<br />

T g<br />

The driving force for heat transfer is<br />

the temperature difference between<br />

the liquid film <strong>and</strong> the bulk <strong>of</strong> the<br />

carrier gas. For mass transfer, it is due<br />

to the difference in water vapor<br />

pressure (or vapor concentration C) on<br />

the liquid film surface <strong>and</strong> partial<br />

pressure <strong>of</strong> water vapor in the bulk<br />

gas. The gas liquid contact area is a<br />

function <strong>of</strong> the geometric configuration<br />

<strong>of</strong> the exchanger, packing shape <strong>and</strong><br />

size, <strong>and</strong> liquid <strong>and</strong> gas flow rates.<br />

Packing<br />

surface<br />

Bulk liquid<br />

m v<br />

Liquid-gas<br />

interface<br />

C g<br />

Bulk<br />

gas<br />

Figure 2.5: Finite element at the liquidair<br />

interface in direct contact heat <strong>and</strong><br />

mass exchangers<br />

2.8.3 Lumped model analysis<br />

In this section a simplified lumped model <strong>of</strong> a HDH system as shown in Figure (2.4)<br />

will be developed to explain how it works. Such a framework might help in<br />

interpretation <strong>and</strong> making sense <strong>of</strong> literature results, which will be presented in the<br />

following parts <strong>of</strong> this chapter.<br />

31