Experimental and Numerical Analysis of a PCM-Supported ...

Experimental and Numerical Analysis of a PCM-Supported ...

Experimental and Numerical Analysis of a PCM-Supported ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

melt <strong>and</strong> freeze without segregation since they freeze to an intimate mixture <strong>of</strong><br />

crystals, leaving little opportunity for the components to separate [98].<br />

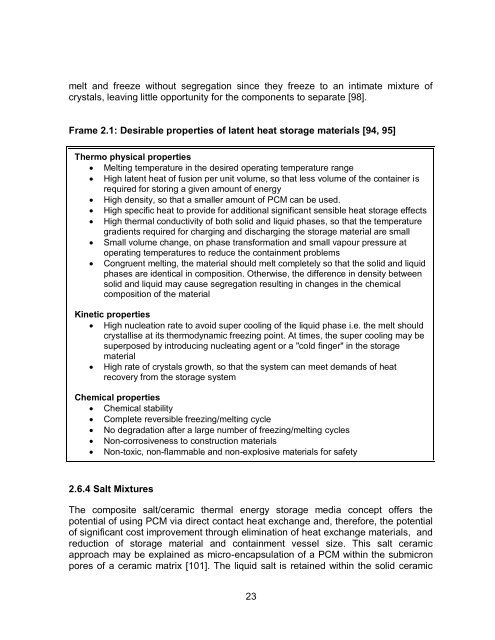

Frame 2.1: Desirable properties <strong>of</strong> latent heat storage materials [94, 95]<br />

Thermo physical properties<br />

Melting temperature in the desired operating temperature range<br />

High latent heat <strong>of</strong> fusion per unit volume, so that less volume <strong>of</strong> the container is<br />

required for storing a given amount <strong>of</strong> energy<br />

High density, so that a smaller amount <strong>of</strong> <strong>PCM</strong> can be used.<br />

High specific heat to provide for additional significant sensible heat storage effects<br />

High thermal conductivity <strong>of</strong> both solid <strong>and</strong> liquid phases, so that the temperature<br />

gradients required for charging <strong>and</strong> discharging the storage material are small<br />

Small volume change, on phase transformation <strong>and</strong> small vapour pressure at<br />

operating temperatures to reduce the containment problems<br />

Congruent melting, the material should melt completely so that the solid <strong>and</strong> liquid<br />

phases are identical in composition. Otherwise, the difference in density between<br />

solid <strong>and</strong> liquid may cause segregation resulting in changes in the chemical<br />

composition <strong>of</strong> the material<br />

Kinetic properties<br />

High nucleation rate to avoid super cooling <strong>of</strong> the liquid phase i.e. the melt should<br />

crystallise at its thermodynamic freezing point. At times, the super cooling may be<br />

superposed by introducing nucleating agent or a "cold finger" in the storage<br />

material<br />

High rate <strong>of</strong> crystals growth, so that the system can meet dem<strong>and</strong>s <strong>of</strong> heat<br />

recovery from the storage system<br />

Chemical properties<br />

Chemical stability<br />

Complete reversible freezing/melting cycle<br />

No degradation after a large number <strong>of</strong> freezing/melting cycles<br />

Non-corrosiveness to construction materials<br />

Non-toxic, non-flammable <strong>and</strong> non-explosive materials for safety<br />

2.6.4 Salt Mixtures<br />

The composite salt/ceramic thermal energy storage media concept <strong>of</strong>fers the<br />

potential <strong>of</strong> using <strong>PCM</strong> via direct contact heat exchange <strong>and</strong>, therefore, the potential<br />

<strong>of</strong> significant cost improvement through elimination <strong>of</strong> heat exchange materials, <strong>and</strong><br />

reduction <strong>of</strong> storage material <strong>and</strong> containment vessel size. This salt ceramic<br />

approach may be explained as micro-encapsulation <strong>of</strong> a <strong>PCM</strong> within the submicron<br />

pores <strong>of</strong> a ceramic matrix [101]. The liquid salt is retained within the solid ceramic<br />

23