Experimental and Numerical Analysis of a PCM-Supported ...

Experimental and Numerical Analysis of a PCM-Supported ...

Experimental and Numerical Analysis of a PCM-Supported ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

the specified boundary <strong>and</strong> weather conditions, especially that the distillate rate also<br />

decreases below the optimum point at G/L hw =0.67. The optimum theoretical mass<br />

flow ratio would be selected as the intersection point at G/L hw =1.8. However, it is<br />

believed that the right decision depends on the energy source <strong>and</strong> cost, for instance<br />

if the energy is supplied through a waste heat source or has a very low cost the<br />

decision then maybe to adopt the highest distillation rate as the main criterion. It can<br />

also be observed that the impact <strong>of</strong> increasing G/L hw is more pronounced on the<br />

distillate rate than the GOR between the intersection point <strong>and</strong> the maximum<br />

distillation rate. Thus the optimum point would be selected as the mean value<br />

between G/L hw =0.67 <strong>and</strong> G/L hw =1, i.e. ≈0.8-0.9.<br />

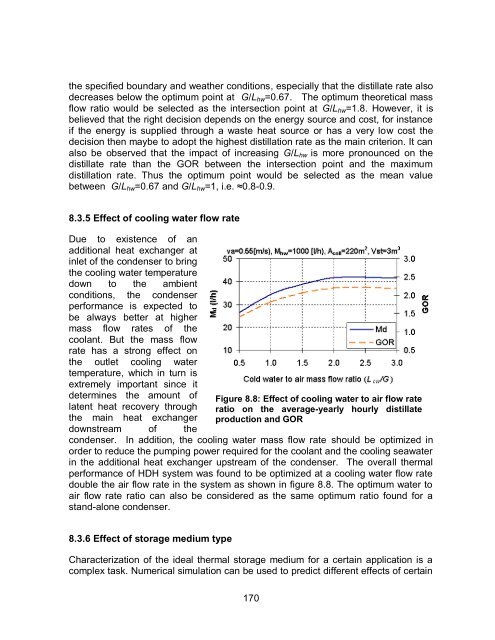

8.3.5 Effect <strong>of</strong> cooling water flow rate<br />

Due to existence <strong>of</strong> an<br />

additional heat exchanger at<br />

inlet <strong>of</strong> the condenser to bring<br />

the cooling water temperature<br />

down to the ambient<br />

conditions, the condenser<br />

performance is expected to<br />

be always better at higher<br />

mass flow rates <strong>of</strong> the<br />

coolant. But the mass flow<br />

rate has a strong effect on<br />

the outlet cooling water<br />

temperature, which in turn is<br />

extremely important since it<br />

determines the amount <strong>of</strong><br />

latent heat recovery through<br />

the main heat exchanger<br />

downstream <strong>of</strong> the<br />

Figure 8.8: Effect <strong>of</strong> cooling water to air flow rate<br />

ratio on the average-yearly hourly distillate<br />

production <strong>and</strong> GOR<br />

condenser. In addition, the cooling water mass flow rate should be optimized in<br />

order to reduce the pumping power required for the coolant <strong>and</strong> the cooling seawater<br />

in the additional heat exchanger upstream <strong>of</strong> the condenser. The overall thermal<br />

performance <strong>of</strong> HDH system was found to be optimized at a cooling water flow rate<br />

double the air flow rate in the system as shown in figure 8.8. The optimum water to<br />

air flow rate ratio can also be considered as the same optimum ratio found for a<br />

st<strong>and</strong>-alone condenser.<br />

8.3.6 Effect <strong>of</strong> storage medium type<br />

Characterization <strong>of</strong> the ideal thermal storage medium for a certain application is a<br />

complex task. <strong>Numerical</strong> simulation can be used to predict different effects <strong>of</strong> certain<br />

170