Experimental and Numerical Analysis of a PCM-Supported ...

Experimental and Numerical Analysis of a PCM-Supported ...

Experimental and Numerical Analysis of a PCM-Supported ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

evaporation rate on the hot water load with reference to air as a very poor<br />

conductive medium.<br />

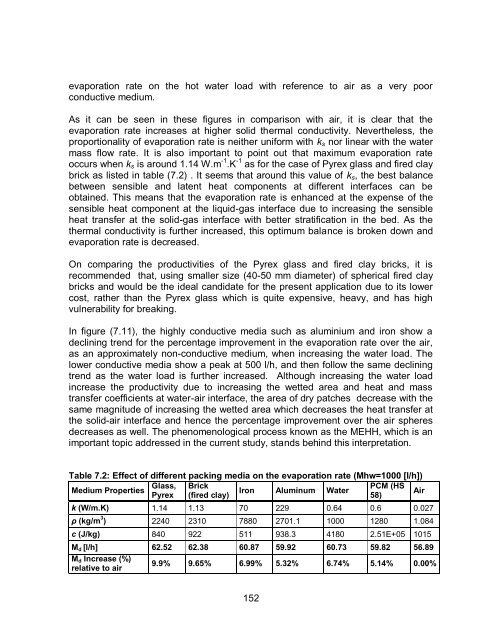

As it can be seen in these figures in comparison with air, it is clear that the<br />

evaporation rate increases at higher solid thermal conductivity. Nevertheless, the<br />

proportionality <strong>of</strong> evaporation rate is neither uniform with k s nor linear with the water<br />

mass flow rate. It is also important to point out that maximum evaporation rate<br />

occurs when k s is around 1.14 W.m -1 .K -1 as for the case <strong>of</strong> Pyrex glass <strong>and</strong> fired clay<br />

brick as listed in table (7.2) . It seems that around this value <strong>of</strong> k s , the best balance<br />

between sensible <strong>and</strong> latent heat components at different interfaces can be<br />

obtained. This means that the evaporation rate is enhanced at the expense <strong>of</strong> the<br />

sensible heat component at the liquid-gas interface due to increasing the sensible<br />

heat transfer at the solid-gas interface with better stratification in the bed. As the<br />

thermal conductivity is further increased, this optimum balance is broken down <strong>and</strong><br />

evaporation rate is decreased.<br />

On comparing the productivities <strong>of</strong> the Pyrex glass <strong>and</strong> fired clay bricks, it is<br />

recommended that, using smaller size (40-50 mm diameter) <strong>of</strong> spherical fired clay<br />

bricks <strong>and</strong> would be the ideal c<strong>and</strong>idate for the present application due to its lower<br />

cost, rather than the Pyrex glass which is quite expensive, heavy, <strong>and</strong> has high<br />

vulnerability for breaking.<br />

In figure (7.11), the highly conductive media such as aluminium <strong>and</strong> iron show a<br />

declining trend for the percentage improvement in the evaporation rate over the air,<br />

as an approximately non-conductive medium, when increasing the water load. The<br />

lower conductive media show a peak at 500 l/h, <strong>and</strong> then follow the same declining<br />

trend as the water load is further increased. Although increasing the water load<br />

increase the productivity due to increasing the wetted area <strong>and</strong> heat <strong>and</strong> mass<br />

transfer coefficients at water-air interface, the area <strong>of</strong> dry patches decrease with the<br />

same magnitude <strong>of</strong> increasing the wetted area which decreases the heat transfer at<br />

the solid-air interface <strong>and</strong> hence the percentage improvement over the air spheres<br />

decreases as well. The phenomenological process known as the MEHH, which is an<br />

important topic addressed in the current study, st<strong>and</strong>s behind this interpretation.<br />

Table 7.2: Effect <strong>of</strong> different packing media on the evaporation rate (Mhw=1000 [l/h])<br />

Glass, Brick<br />

<strong>PCM</strong> (HS<br />

Medium Properties<br />

Iron Aluminum Water<br />

Air<br />

Pyrex (fired clay)<br />

58)<br />

k (W/m.K) 1.14 1.13 70 229 0.64 0.6 0.027<br />

ρ (kg/m 3 ) 2240 2310 7880 2701.1 1000 1280 1.084<br />

c (J/kg) 840 922 511 938.3 4180 2.51E+05 1015<br />

M d [l/h] 62.52 62.38 60.87 59.92 60.73 59.82 56.89<br />

M d Increase (%)<br />

relative to air<br />

9.9% 9.65% 6.99% 5.32% 6.74% 5.14% 0.00%<br />

152