Experimental and Numerical Analysis of a PCM-Supported ...

Experimental and Numerical Analysis of a PCM-Supported ...

Experimental and Numerical Analysis of a PCM-Supported ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Q m H<br />

c<br />

( T T1)<br />

c ( T 2 T<br />

)<br />

(2.2)<br />

m<br />

s<br />

m<br />

l<br />

m<br />

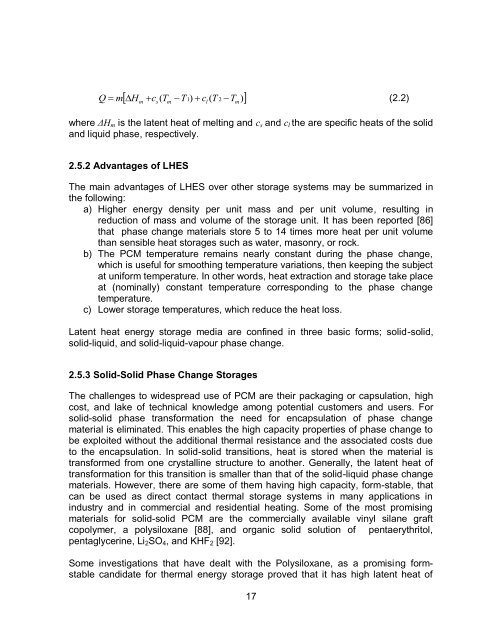

where ΔH m is the latent heat <strong>of</strong> melting <strong>and</strong> c s <strong>and</strong> c l the are specific heats <strong>of</strong> the solid<br />

<strong>and</strong> liquid phase, respectively.<br />

2.5.2 Advantages <strong>of</strong> LHES<br />

The main advantages <strong>of</strong> LHES over other storage systems may be summarized in<br />

the following:<br />

a) Higher energy density per unit mass <strong>and</strong> per unit volume, resulting in<br />

reduction <strong>of</strong> mass <strong>and</strong> volume <strong>of</strong> the storage unit. It has been reported [86]<br />

that phase change materials store 5 to 14 times more heat per unit volume<br />

than sensible heat storages such as water, masonry, or rock.<br />

b) The <strong>PCM</strong> temperature remains nearly constant during the phase change,<br />

which is useful for smoothing temperature variations, then keeping the subject<br />

at uniform temperature. In other words, heat extraction <strong>and</strong> storage take place<br />

at (nominally) constant temperature corresponding to the phase change<br />

temperature.<br />

c) Lower storage temperatures, which reduce the heat loss.<br />

Latent heat energy storage media are confined in three basic forms; solid-solid,<br />

solid-liquid, <strong>and</strong> solid-liquid-vapour phase change.<br />

2.5.3 Solid-Solid Phase Change Storages<br />

The challenges to widespread use <strong>of</strong> <strong>PCM</strong> are their packaging or capsulation, high<br />

cost, <strong>and</strong> lake <strong>of</strong> technical knowledge among potential customers <strong>and</strong> users. For<br />

solid-solid phase transformation the need for encapsulation <strong>of</strong> phase change<br />

material is eliminated. This enables the high capacity properties <strong>of</strong> phase change to<br />

be exploited without the additional thermal resistance <strong>and</strong> the associated costs due<br />

to the encapsulation. In solid-solid transitions, heat is stored when the material is<br />

transformed from one crystalline structure to another. Generally, the latent heat <strong>of</strong><br />

transformation for this transition is smaller than that <strong>of</strong> the solid-liquid phase change<br />

materials. However, there are some <strong>of</strong> them having high capacity, form-stable, that<br />

can be used as direct contact thermal storage systems in many applications in<br />

industry <strong>and</strong> in commercial <strong>and</strong> residential heating. Some <strong>of</strong> the most promising<br />

materials for solid-solid <strong>PCM</strong> are the commercially available vinyl silane graft<br />

copolymer, a polysiloxane [88], <strong>and</strong> organic solid solution <strong>of</strong> pentaerythritol,<br />

pentaglycerine, Li 2 SO 4 , <strong>and</strong> KHF 2 [92].<br />

Some investigations that have dealt with the Polysiloxane, as a promising formstable<br />

c<strong>and</strong>idate for thermal energy storage proved that it has high latent heat <strong>of</strong><br />

17