MAINTENANCE MANUAL - Meritor

MAINTENANCE MANUAL - Meritor

MAINTENANCE MANUAL - Meritor

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Hazard Alert Messages<br />

Read and observe all Warning and Caution<br />

hazard alert messages in this publication. They<br />

provide information that can help prevent serious<br />

personal injury, damage to components, or<br />

both.<br />

WARNING<br />

To prevent serious eye injury, always wear<br />

safe eye protection when you perform vehicle<br />

maintenance or service.<br />

Use a brass or synthetic mallet for assembly<br />

and disassembly procedures. Do not hit steel<br />

parts with a steel hammer. Pieces of a part can<br />

break off. Serious personal injury and damage<br />

to components can result.<br />

Observe all warnings and cautions provided<br />

by the press manufacturer to avoid damage to<br />

components and serious personal injury.<br />

Axle Shafts from the Axle Housing<br />

WARNING<br />

Park the vehicle on a level surface. Block the<br />

wheels to prevent the vehicle from moving.<br />

Support the vehicle with safety stands. Do not<br />

work under a vehicle supported only by jacks.<br />

Jacks can slip or fall over. Serious personal<br />

injury and damage to components can result.<br />

1. Park the vehicle on a level surface. Block the<br />

wheels to prevent the vehicle from moving.<br />

Set the parking brake.<br />

2.Use a jack to raise the vehicle so that the wheels<br />

to be serviced are off the ground. Support the<br />

vehicle with safety stands.<br />

3. Remove the oil drain plug from the bottom<br />

of the axle housing. Drain the axle lubricant<br />

from the housing assembly.<br />

<strong>MAINTENANCE</strong> <strong>MANUAL</strong><br />

Removal and Disassembly<br />

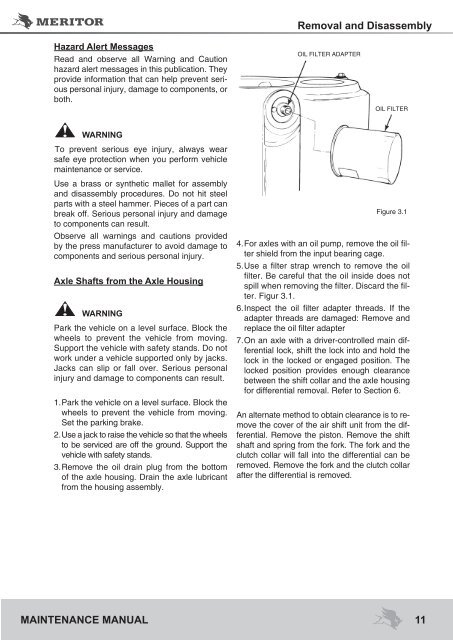

OIL FILTER ADAPTER<br />

OIL FILTER<br />

Figure 3.1<br />

4.For axles with an oil pump, remove the oil filter<br />

shield from the input bearing cage.<br />

5.Use a filter strap wrench to remove the oil<br />

filter. Be careful that the oil inside does not<br />

spill when removing the filter. Discard the filter.<br />

Figur 3.1.<br />

6.Inspect the oil filter adapter threads. If the<br />

adapter threads are damaged: Remove and<br />

replace the oil filter adapter<br />

7. On an axle with a driver-controlled main differential<br />

lock, shift the lock into and hold the<br />

lock in the locked or engaged position. The<br />

locked position provides enough clearance<br />

between the shift collar and the axle housing<br />

for differential removal. Refer to Section 6.<br />

An alternate method to obtain clearance is to remove<br />

the cover of the air shift unit from the differential.<br />

Remove the piston. Remove the shift<br />

shaft and spring from the fork. The fork and the<br />

clutch collar will fall into the differential can be<br />

removed. Remove the fork and the clutch collar<br />

after the differential is removed.<br />

11