MAINTENANCE MANUAL - Meritor

MAINTENANCE MANUAL - Meritor

MAINTENANCE MANUAL - Meritor

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Assembly and Installation<br />

22. Install the washer and the nut the drive pinion.<br />

Prevent the drive pinion assembly from<br />

rotating by using of device or tool to hold<br />

the teeth of the helical driven gear or place<br />

wood blocks between the head of the pinion<br />

and the differential case wall. Tighten<br />

the nut to the specified torque. See Section<br />

8. Remove the holding tool or the wood<br />

blocks.<br />

23. Use an inch-pound torque wrench or a<br />

spring scale to inspect the preload of the<br />

bearings on the drive pinion.<br />

Torque Wrench Method<br />

1. Place an inch-pound (N.m) torque wrench<br />

and the correct socket in the drive pinion nut.<br />

Figure 5.16.<br />

REAR SIDE GEAR<br />

BEARING CUP<br />

CARRIER INPUT<br />

BORE<br />

Figure 5.16<br />

2. Use the torque wrench to rotate the drive pinion<br />

assembly. Inspect and record the torque<br />

level. Read while rotating the assembly. Record<br />

the dynamic or rotating torque not the<br />

starting torque.<br />

3. The preload of the drive pinion bearings must<br />

be within the following limits.<br />

• For new pinion bearings: 5-45 lb-in (0.56-<br />

5.08 N.m) rotational torque .<br />

• For used pinion bearings: 10-30 lb-in (1.13-<br />

3.39 N.m ) rotational torque .<br />

• If the preload is not within the specified limits,<br />

remove and replace the spacer between<br />

the outer bearing cone and the helical driven<br />

gear. See the procedure below:<br />

• To decrease the preload, install a thicker<br />

spacer.<br />

• To increase the preload, install a thinner spacer.<br />

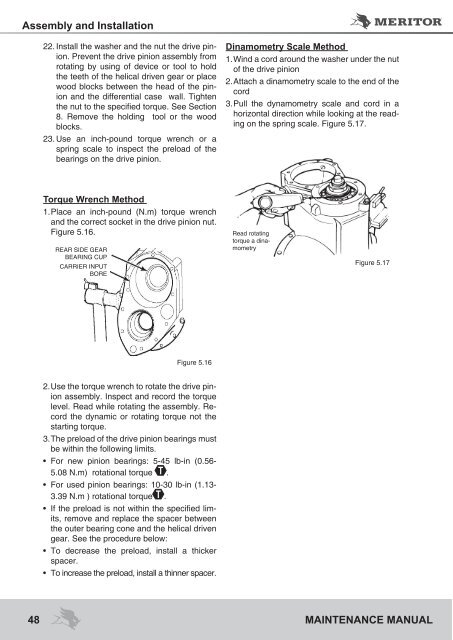

Dinamometry Scale Method<br />

1. Wind a cord around the washer under the nut<br />

of the drive pinion<br />

2. Attach a dinamometry scale to the end of the<br />

cord<br />

3. Pull the dynamometry scale and cord in a<br />

horizontal direction while looking at the reading<br />

on the spring scale. Figure 5.17.<br />

Read rotating<br />

torque a dinamometry<br />

Figure 5.17<br />

48 <strong>MAINTENANCE</strong> <strong>MANUAL</strong>