MAINTENANCE MANUAL - Meritor

MAINTENANCE MANUAL - Meritor

MAINTENANCE MANUAL - Meritor

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Driver-Controlled Main Differential Lock<br />

10.Install the manual engaging capscrew into<br />

the threaded hole in the center of the cylinder<br />

cover or cylinder.<br />

WARNING<br />

THERE WILL BE A SMALL AMOUNT OF<br />

SPRING RESISTANCE FELT WHEN YOU TURN<br />

IN THE <strong>MANUAL</strong> ENGAGING CAPSCREW. IF A<br />

HIGH RESISTANCE IS FELT BEFORE REACH-<br />

ING THE LOCkED OR ENGAGED POSITION,<br />

STOP TURNING THE CAPSCREW, OR THE<br />

COVER, FORk AND CAPSCREW THREADS<br />

WILL BE DAMAGED.<br />

11. Turn the manual adjusting capscrew to the<br />

right until the head is approximately 0.25-inch<br />

(6 mm) from the cylinder cover. Do not turn<br />

the capscrew beyond its normal stop.<br />

A high resistance on the capscrew indicates<br />

that the splines of the shift collar and the differential<br />

case half are not aligned or engaged. To<br />

align the splines, use the following procedure.<br />

A. Rotate the left-hand wheel to align the splines<br />

of the shift collar and case half while you turn in<br />

the manual engaging capscrews.<br />

B. When the normal amount of spring resistance<br />

is again felt on the capscrew, the<br />

splines are engaged. Continue to turn in the<br />

manual engaging capscrew until the head<br />

is approximately 0.25-inch (6 mm) from the<br />

cylinder cover. The capscrew is now in the<br />

service position and the main differential lock<br />

is completely engaged.<br />

12. Remove the differential from the axle housing.<br />

See the Section 3.<br />

13.Release the differential lock by removing<br />

the manual engaging capscrew and seal<br />

from the cylinder cover or cylinder.<br />

Auxiliary Air Supply Method<br />

1. Park the vehicle on a level surface. Block the<br />

wheels to prevent the vehicle from moving.<br />

2.Use a jack to raise the left-hand wheel of the<br />

drive axle. Place a safety stand under the lefthand<br />

axle housing leg to support the vehicle in<br />

the raised position.<br />

3. Remove the drain plug from the bottom of the<br />

housing and drain the lubricant.<br />

4. Disconnect the driveline from the input fork.<br />

5. Disconnect the vehicle air line from the interaxle<br />

differential and main differential lock actuator<br />

assemblies.<br />

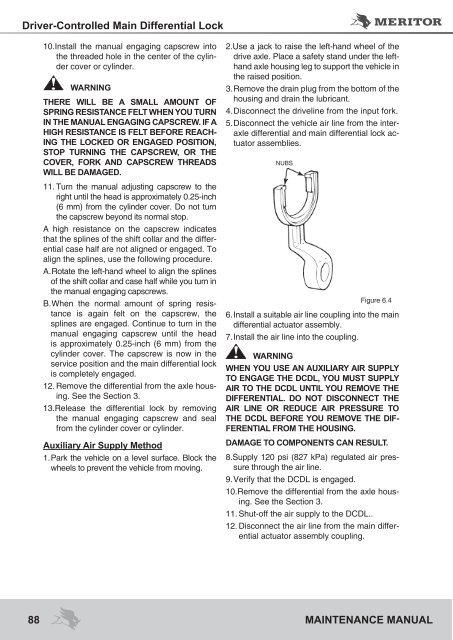

Figure 6.4<br />

6. Install a suitable air line coupling into the main<br />

differential actuator assembly.<br />

7. Install the air line into the coupling.<br />

WARNING<br />

WHEN YOU USE AN AUXILIARY AIR SUPPLY<br />

TO ENGAGE THE DCDL, YOU MUST SUPPLY<br />

AIR TO THE DCDL UNTIL YOU REMOVE THE<br />

DIFFERENTIAL. DO NOT DISCONNECT THE<br />

AIR LINE OR REDUCE AIR PRESSURE TO<br />

THE DCDL BEFORE YOU REMOVE THE DIF-<br />

FERENTIAL FROM THE HOUSING.<br />

DAMAGE TO COMPONENTS CAN RESULT.<br />

8.Supply 120 psi (827 kPa) regulated air pressure<br />

through the air line.<br />

9. Verify that the DCDL is engaged.<br />

10.Remove the differential from the axle housing.<br />

See the Section 3.<br />

11. Shut-off the air supply to the DCDL..<br />

12. Disconnect the air line from the main differential<br />

actuator assembly coupling.<br />

88 <strong>MAINTENANCE</strong> <strong>MANUAL</strong><br />

NUBS