MAINTENANCE MANUAL - Meritor

MAINTENANCE MANUAL - Meritor

MAINTENANCE MANUAL - Meritor

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

CAUTION<br />

USE A PRESS AND A SLEEVE OR FORk IN-<br />

STALLATION TOOL TO INSTALL THE FORk.<br />

DO NOT USE A HAMMER OR MALLET. USING<br />

A HAMMER OR MALLET CAN DAMAGE THE<br />

BEARINGS, FORk OR FLANGE.<br />

If a fork is removed after it has been partially<br />

or fully installed, the unitized pinion seal will<br />

be damaged. Remove and discard the original<br />

unitized pinion seal and replace it with a new<br />

one.<br />

If a fork has been installed into the unitized pinion<br />

seal and then removed, the inner sleeve of the<br />

seal will be damaged. Install a new seal.<br />

3. Use a press and sleeve or an installation<br />

tool to install the fork or flange in the output<br />

shaft. Verify that the splines inside the fork<br />

or flange are aligned with the splines on the<br />

toutput shaft. If a press and sleeve are used,<br />

verify that the output shaft is supported.<br />

4. Install the nut that fastens the output fork or<br />

flange to the output shaft. Place a holding tool<br />

on the fork or flange and tighten the nut to the<br />

specified torque. See the Section 8.<br />

5. Rotate the fork at least one full turn after<br />

the fork nut is tightened to the correct<br />

torque specification. This ensures correct<br />

seating of the seal.<br />

Differential Assembly of the Axle Housing<br />

WARNING<br />

Solvent cleaners can be flammable, poisonous<br />

and cause burns. Examples of solvent cleaners<br />

are carbon tetrachloride, and emulsion type and<br />

petroleum base cleaners. Read the manufacturer’s<br />

instructions before using a solvent cleaner,<br />

then carefully follow the instructions. Also follow<br />

the procedures below:<br />

• Wear safe eye protection.<br />

• Wear clothing that protects your skin.<br />

• Work in a well ventilated area.<br />

• Do not use gasoline, or solvents that contain<br />

gasoline. Gasoline can explode.<br />

<strong>MAINTENANCE</strong> <strong>MANUAL</strong><br />

Assembly and Installation<br />

• You must use hot solution tanks or alkaline<br />

solutions correctly. Read the manufacturer’s<br />

instructions before using hot solution<br />

tanks and alkaline solutions. Then<br />

carefully follow the instructions<br />

1. Use a cleaning solvent and rags to clean the<br />

inside of the axle housing and the differential<br />

mounting surface. See the Section 4.<br />

2. Inspect the axle housing for damage. Repair or<br />

replace the axle housing. See the Section 4.<br />

3. Check for loose studs, if equipped, in the<br />

mounting surface of the housing where the<br />

differential fastens. Remove and clean<br />

the studs that are loose.<br />

4. Install the studs in the axle housing. See the procedure<br />

in this section. Tighten the studs to 150-<br />

230 lb-ft (203-312 Nem). .<br />

WARNING<br />

When you apply some silicone gasket materials,<br />

a small amount of acid vapor is present. To prevent<br />

serious personal injury, ensure that the work<br />

area is well-ventilated. Read the manufacturer’s<br />

instructions before using a silicone gasket material,<br />

then carefully follow the instructions. If a<br />

silicone gasket material gets into your eyes, follow<br />

the manufacturer’s emergency procedures.<br />

Have your eyes checked by a physician as soon<br />

as possible.<br />

CAUTION<br />

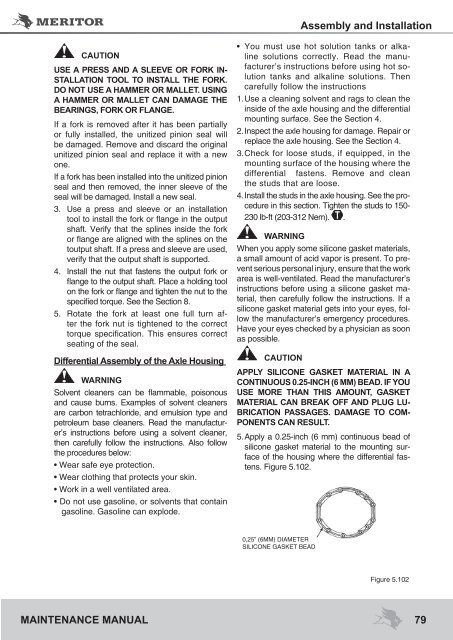

APPLY SILICONE GASkET MATERIAL IN A<br />

CONTINUOUS 0.25-INCH (6 MM) BEAD. IF YOU<br />

USE MORE THAN THIS AMOUNT, GASkET<br />

MATERIAL CAN BREAk OFF AND PLUG LU-<br />

BRICATION PASSAGES. DAMAGE TO COM-<br />

PONENTS CAN RESULT.<br />

5. Apply a 0.25-inch (6 mm) continuous bead of<br />

silicone gasket material to the mounting surface<br />

of the housing where the differential fastens.<br />

Figure 5.102.<br />

0,25” (6MM) DIAMETER<br />

SILICONE GASKET BEAD<br />

Figure 5.102<br />

79