MAINTENANCE MANUAL - Meritor

MAINTENANCE MANUAL - Meritor

MAINTENANCE MANUAL - Meritor

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Assembly and Installation<br />

KEY “T”<br />

6. Proceed to check ring gear runout.<br />

BARS MUST NOT<br />

TOUCH BEARING<br />

Figure 5.38<br />

SQUEEZE EACH<br />

RING IN A GROOVE<br />

Figure 5.39<br />

Large Micrometer Method<br />

1.Hand-tighten the adjusting rings against the<br />

main differential bearings.<br />

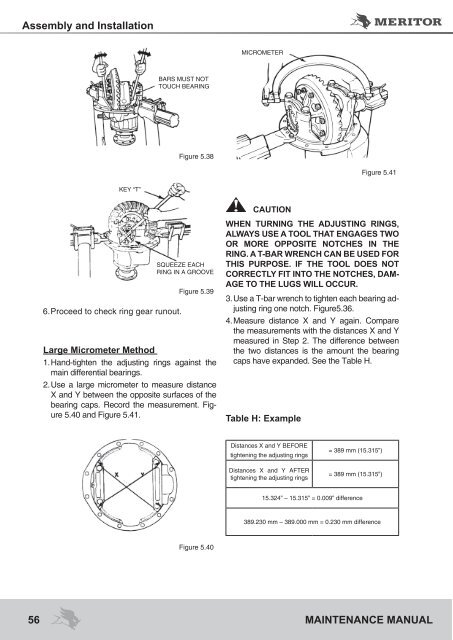

2. Use a large micrometer to measure distance<br />

X and Y between the opposite surfaces of the<br />

bearing caps. Record the measurement. Figure<br />

5.40 and Figure 5.41.<br />

Figure 5.40<br />

MICROMETER<br />

CAUTION<br />

Figure 5.41<br />

WHEN TURNING THE ADjUSTING RINGS,<br />

ALWAYS USE A TOOL THAT ENGAGES TWO<br />

OR MORE OPPOSITE NOTCHES IN THE<br />

RING. A T-BAR WRENCH CAN BE USED FOR<br />

THIS PURPOSE. IF THE TOOL DOES NOT<br />

CORRECTLY FIT INTO THE NOTCHES, DAM-<br />

AGE TO THE LUGS WILL OCCUR.<br />

3. Use a T-bar wrench to tighten each bearing adjusting<br />

ring one notch. Figure5.36.<br />

4. Measure distance X and Y again. Compare<br />

the measurements with the distances X and Y<br />

measured in Step 2. The difference between<br />

the two distances is the amount the bearing<br />

caps have expanded. See the Table H.<br />

Table H: Example<br />

Distances X and Y BEFORE<br />

tightening the adjusting rings<br />

Distances X and Y AFTER<br />

tightening the adjusting rings<br />

= 389 mm (15.315”)<br />

= 389 mm (15.315”)<br />

15.324” – 15.315” = 0.009” difference<br />

389.230 mm – 389.000 mm = 0.230 mm difference<br />

56 <strong>MAINTENANCE</strong> <strong>MANUAL</strong>