MAINTENANCE MANUAL - Meritor

MAINTENANCE MANUAL - Meritor

MAINTENANCE MANUAL - Meritor

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Assembly and Installation<br />

10. If disassembled, assemble the inter-axle<br />

differential.<br />

A. Apply axle lubricant to all of the inter-axle<br />

differential parts.<br />

B. Install the pinion gears and the thrust washers<br />

in the spider.<br />

C. Place the spider and pinion assembly in<br />

one of the case halves of the inter-axle<br />

differential.<br />

D. Install the remaining case half over the first<br />

case half. Verify that the marks on each case<br />

half are aligned.<br />

E. Install four of the capscrews that fasten the<br />

case halves together. Install the capscrews<br />

so that the capscrews are the same distance<br />

away from each other. Equally tighten the<br />

capscrews to bring the case halves together.<br />

F. Install the rest of the capscrews. Tighten<br />

the capscrews to 45-55 lb-ft (60-75 Nm).<br />

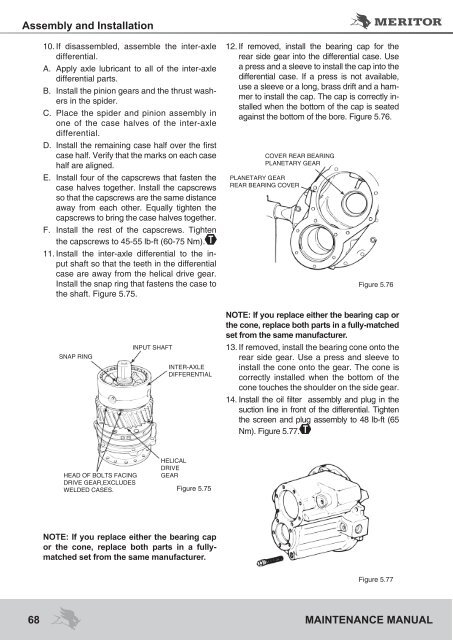

11. Install the inter-axle differential to the input<br />

shaft so that the teeth in the differential<br />

case are away from the helical drive gear.<br />

Install the snap ring that fastens the case to<br />

the shaft. Figure 5.75.<br />

SNAP RING<br />

HEAD OF BOLTS FACING<br />

DRIVE GEAR,EXCLUDES<br />

WELDED CASES.<br />

INPUT SHAFT<br />

INTER-AXLE<br />

DIFFERENTIAL<br />

HELICAL<br />

DRIVE<br />

GEAR<br />

Figure 5.75<br />

NOTE: If you replace either the bearing cap<br />

or the cone, replace both parts in a fullymatched<br />

set from the same manufacturer.<br />

12. If removed, install the bearing cap for the<br />

rear side gear into the differential case. Use<br />

a press and a sleeve to install the cap into the<br />

differential case. If a press is not available,<br />

use a sleeve or a long, brass drift and a hammer<br />

to install the cap. The cap is correctly installed<br />

when the bottom of the cap is seated<br />

against the bottom of the bore. Figure 5.76.<br />

COVER REAR BEARING<br />

PLANETARY GEAR<br />

PLANETARY GEAR<br />

REAR BEARING COVER<br />

Figure 5.76<br />

NOTE: If you replace either the bearing cap or<br />

the cone, replace both parts in a fully-matched<br />

set from the same manufacturer.<br />

13. If removed, install the bearing cone onto the<br />

rear side gear. Use a press and sleeve to<br />

install the cone onto the gear. The cone is<br />

correctly installed when the bottom of the<br />

cone touches the shoulder on the side gear.<br />

14. Install the oil filter assembly and plug in the<br />

suction line in front of the differential. Tighten<br />

the screen and plug assembly to 48 lb-ft (65<br />

Nm). Figure 5.77.<br />

Figure 5.77<br />

68 <strong>MAINTENANCE</strong> <strong>MANUAL</strong>