MAINTENANCE MANUAL - Meritor

MAINTENANCE MANUAL - Meritor

MAINTENANCE MANUAL - Meritor

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Assembly and Installation<br />

CAUTION<br />

THE BEARING CAPS MUST BE CORRECT-<br />

LY INSTALLED OR THE ADjUSTING RINGS<br />

WILL BE DAMAGED BY CROSS-THREAD-<br />

ING. FORCING THE CAPS INTO POSITION<br />

CAN DAMAGE THE CAPS AND THE DIF-<br />

FERENTIAL CASE.<br />

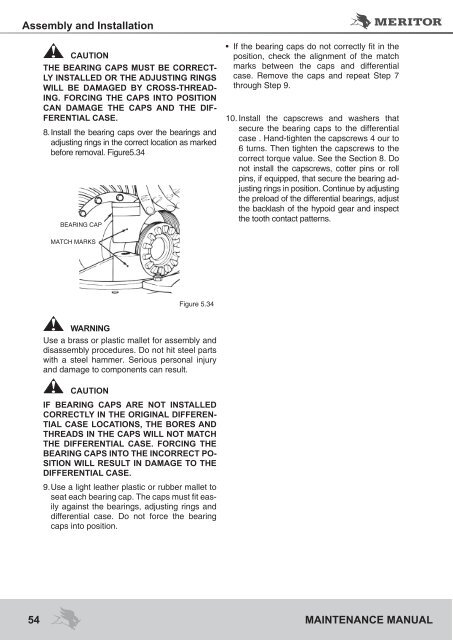

8. Install the bearing caps over the bearings and<br />

adjusting rings in the correct location as marked<br />

before removal. Figure5.34<br />

BEARING CAP<br />

MATCH MARKS<br />

Figure 5.34<br />

WARNING<br />

Use a brass or plastic mallet for assembly and<br />

disassembly procedures. Do not hit steel parts<br />

with a steel hammer. Serious personal injury<br />

and damage to components can result.<br />

CAUTION<br />

IF BEARING CAPS ARE NOT INSTALLED<br />

CORRECTLY IN THE ORIGINAL DIFFEREN-<br />

TIAL CASE LOCATIONS, THE BORES AND<br />

THREADS IN THE CAPS WILL NOT MATCH<br />

THE DIFFERENTIAL CASE. FORCING THE<br />

BEARING CAPS INTO THE INCORRECT PO-<br />

SITION WILL RESULT IN DAMAGE TO THE<br />

DIFFERENTIAL CASE.<br />

9. Use a light leather plastic or rubber mallet to<br />

seat each bearing cap. The caps must fit easily<br />

against the bearings, adjusting rings and<br />

differential case. Do not force the bearing<br />

caps into position.<br />

• If the bearing caps do not correctly fit in the<br />

position, check the alignment of the match<br />

marks between the caps and differential<br />

case. Remove the caps and repeat Step 7<br />

through Step 9.<br />

10. Install the capscrews and washers that<br />

secure the bearing caps to the differential<br />

case . Hand-tighten the capscrews 4 our to<br />

6 turns. Then tighten the capscrews to the<br />

correct torque value. See the Section 8. Do<br />

not install the capscrews, cotter pins or roll<br />

pins, if equipped, that secure the bearing adjusting<br />

rings in position. Continue by adjusting<br />

the preload of the differential bearings, adjust<br />

the backlash of the hypoid gear and inspect<br />

the tooth contact patterns.<br />

54 <strong>MAINTENANCE</strong> <strong>MANUAL</strong>