MAINTENANCE MANUAL - Meritor

MAINTENANCE MANUAL - Meritor

MAINTENANCE MANUAL - Meritor

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

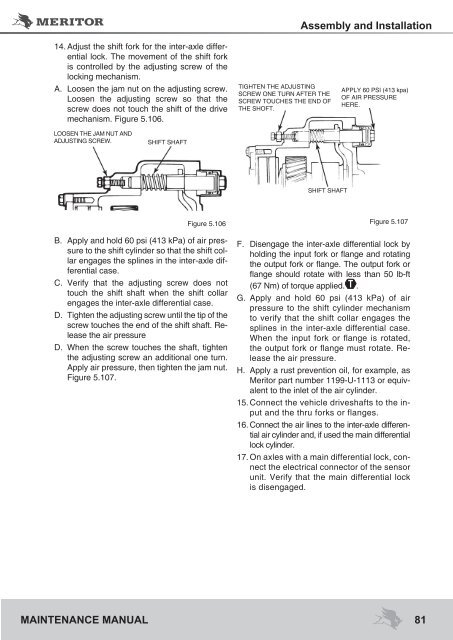

14. Adjust the shift fork for the inter-axle differential<br />

lock. The movement of the shift fork<br />

is controlled by the adjusting screw of the<br />

locking mechanism.<br />

A. Loosen the jam nut on the adjusting screw.<br />

Loosen the adjusting screw so that the<br />

screw does not touch the shift of the drive<br />

mechanism. Figure 5.106.<br />

LOOSEN THE JAM NUT AND<br />

ADJUSTING SCREW.<br />

B. Apply and hold 60 psi (413 kPa) of air pressure<br />

to the shift cylinder so that the shift collar<br />

engages the splines in the inter-axle differential<br />

case.<br />

C. Verify that the adjusting screw does not<br />

touch the shift shaft when the shift collar<br />

engages the inter-axle differential case.<br />

D. Tighten the adjusting screw until the tip of the<br />

screw touches the end of the shift shaft. Release<br />

the air pressure<br />

D. When the screw touches the shaft, tighten<br />

the adjusting screw an additional one turn.<br />

Apply air pressure, then tighten the jam nut.<br />

Figure 5.107.<br />

<strong>MAINTENANCE</strong> <strong>MANUAL</strong><br />

SHIFT SHAFT<br />

Figure 5.106<br />

TIGHTEN THE ADJUSTING<br />

SCREW ONE TURN AFTER THE<br />

SCREW TOUCHES THE END OF<br />

THE SHOFT.<br />

Assembly and Installation<br />

SHIFT SHAFT<br />

APPLY 60 PSI (413 kpa)<br />

OF AIR PRESSURE<br />

HERE.<br />

Figure 5.107<br />

F. Disengage the inter-axle differential lock by<br />

holding the input fork or flange and rotating<br />

the output fork or flange. The output fork or<br />

flange should rotate with less than 50 lb-ft<br />

(67 Nm) of torque applied. .<br />

G. Apply and hold 60 psi (413 kPa) of air<br />

pressure to the shift cylinder mechanism<br />

to verify that the shift collar engages the<br />

splines in the inter-axle differential case.<br />

When the input fork or flange is rotated,<br />

the output fork or flange must rotate. Release<br />

the air pressure.<br />

H. Apply a rust prevention oil, for example, as<br />

<strong>Meritor</strong> part number 1199-U-1113 or equivalent<br />

to the inlet of the air cylinder.<br />

15. Connect the vehicle driveshafts to the input<br />

and the thru forks or flanges.<br />

16. Connect the air lines to the inter-axle differential<br />

air cylinder and, if used the main differential<br />

lock cylinder.<br />

17. On axles with a main differential lock, connect<br />

the electrical connector of the sensor<br />

unit. Verify that the main differential lock<br />

is disengaged.<br />

81