MAINTENANCE MANUAL - Meritor

MAINTENANCE MANUAL - Meritor

MAINTENANCE MANUAL - Meritor

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

NOTE:<br />

Some models use silastic seal instead of<br />

the flat washer in Step E. Also, a roll pin is<br />

installed in the shift shaft and is used as a<br />

stop for the shift shaft spring. It is not necessary<br />

to remove this roll pin during a normal<br />

disassembly.<br />

E. Remove the shift shaft spring and flat washer.<br />

F. Remove the shift fork and continue with Step<br />

11 in the previous procedure.<br />

CAPSCREW AND WASH-<br />

ER, FOUR CORNERS<br />

DCDL Installation<br />

Differential Shift Assembly<br />

WARNING<br />

When you apply some silicone gasket materials, a<br />

small a mount of acid vapor is present. To prevent<br />

serious personal injury, ensure that the work area<br />

is well-ventilated. Read the manufacturer’s instructions<br />

before using a silicone gasket material, then<br />

carefully follow the instructions. If a silicone gasket<br />

material gets into your eyes, follow the manufacturer’s<br />

emergency procedures. Have your eyes<br />

checked by a physician as soon as possible.<br />

Take care when you use Loctite® adhesive to<br />

avoid serious personal injury. Read the manufacturer’s<br />

instructions before using this product. Follow<br />

the instructions carefully to prevent irritation to<br />

the eyes and skin.<br />

<strong>MAINTENANCE</strong> <strong>MANUAL</strong><br />

TAPA, JUNTA DE COBRE<br />

debajo de la tapa - sólo<br />

Serie 160<br />

Figure 6.14<br />

Driver-Controlled Main Differential Lock<br />

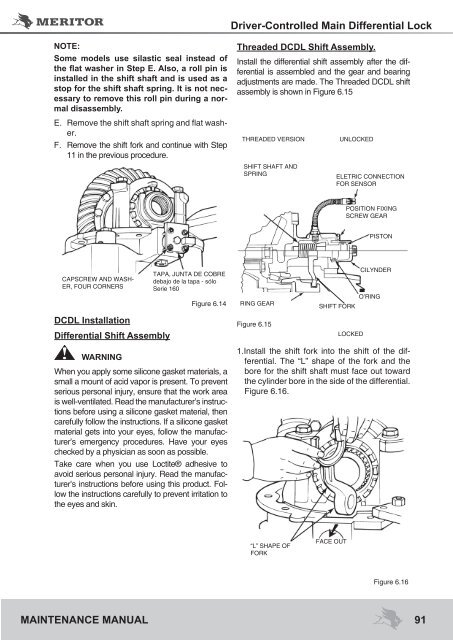

Threaded DCDL Shift Assembly.<br />

Install the differential shift assembly after the differential<br />

is assembled and the gear and bearing<br />

adjustments are made. The Threaded DCDL shift<br />

assembly is shown in Figure 6.15<br />

THREADED VERSION UNLOCKED<br />

SHIFT SHAFT AND<br />

SPRING<br />

RING GEAR<br />

Figure 6.15<br />

ELETRIC CONNECTION<br />

FOR SENSOR<br />

SHIFT FORK<br />

POSITION FIXING<br />

SCREW GEAR<br />

CILYNDER<br />

O’RING<br />

PISTON<br />

1.Install the shift fork into the shift of the differential.<br />

The “L” shape of the fork and the<br />

bore for the shift shaft must face out toward<br />

the cylinder bore in the side of the differential.<br />

Figure 6.16.<br />

“L” SHAPE OF<br />

FORK<br />

FACE OUT<br />

LOCKED<br />

Figure 6.16<br />

91