Radiography in Modern Industry - Kodak

Radiography in Modern Industry - Kodak

Radiography in Modern Industry - Kodak

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

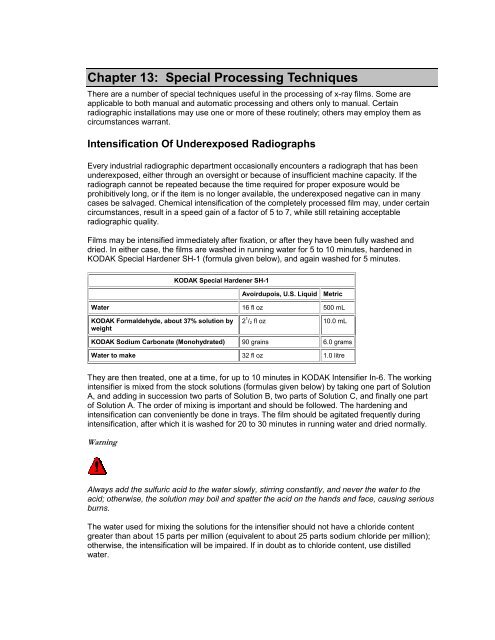

Chapter 13: Special Process<strong>in</strong>g TechniquesThere are a number of special techniques useful <strong>in</strong> the process<strong>in</strong>g of x-ray films. Some areapplicable to both manual and automatic process<strong>in</strong>g and others only to manual. Certa<strong>in</strong>radiographic <strong>in</strong>stallations may use one or more of these rout<strong>in</strong>ely; others may employ them ascircumstances warrant.Intensification Of Underexposed RadiographsEvery <strong>in</strong>dustrial radiographic department occasionally encounters a radiograph that has beenunderexposed, either through an oversight or because of <strong>in</strong>sufficient mach<strong>in</strong>e capacity. If theradiograph cannot be repeated because the time required for proper exposure would beprohibitively long, or if the item is no longer available, the underexposed negative can <strong>in</strong> manycases be salvaged. Chemical <strong>in</strong>tensification of the completely processed film may, under certa<strong>in</strong>circumstances, result <strong>in</strong> a speed ga<strong>in</strong> of a factor of 5 to 7, while still reta<strong>in</strong><strong>in</strong>g acceptableradiographic quality.Films may be <strong>in</strong>tensified immediately after fixation, or after they have been fully washed anddried. In either case, the films are washed <strong>in</strong> runn<strong>in</strong>g water for 5 to 10 m<strong>in</strong>utes, hardened <strong>in</strong>KODAK Special Hardener SH-1 (formula given below), and aga<strong>in</strong> washed for 5 m<strong>in</strong>utes.KODAK Special Hardener SH-1Avoirdupois, U.S. LiquidMetricWater 16 fl oz 500 mLKODAK Formaldehyde, about 37% solution byweight2 1 / 2 fl oz 10.0 mLKODAK Sodium Carbonate (Monohydrated) 90 gra<strong>in</strong>s 6.0 gramsWater to make 32 fl oz 1.0 litreThey are then treated, one at a time, for up to 10 m<strong>in</strong>utes <strong>in</strong> KODAK Intensifier In-6. The work<strong>in</strong>g<strong>in</strong>tensifier is mixed from the stock solutions (formulas given below) by tak<strong>in</strong>g one part of SolutionA, and add<strong>in</strong>g <strong>in</strong> succession two parts of Solution B, two parts of Solution C, and f<strong>in</strong>ally one partof Solution A. The order of mix<strong>in</strong>g is important and should be followed. The harden<strong>in</strong>g and<strong>in</strong>tensification can conveniently be done <strong>in</strong> trays. The film should be agitated frequently dur<strong>in</strong>g<strong>in</strong>tensification, after which it is washed for 20 to 30 m<strong>in</strong>utes <strong>in</strong> runn<strong>in</strong>g water and dried normally.Warn<strong>in</strong>gAlways add the sulfuric acid to the water slowly, stirr<strong>in</strong>g constantly, and never the water to theacid; otherwise, the solution may boil and spatter the acid on the hands and face, caus<strong>in</strong>g seriousburns.The water used for mix<strong>in</strong>g the solutions for the <strong>in</strong>tensifier should not have a chloride contentgreater than about 15 parts per million (equivalent to about 25 parts sodium chloride per million);otherwise, the <strong>in</strong>tensification will be impaired. If <strong>in</strong> doubt as to chloride content, use distilledwater.