Radiography in Modern Industry - Kodak

Radiography in Modern Industry - Kodak

Radiography in Modern Industry - Kodak

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

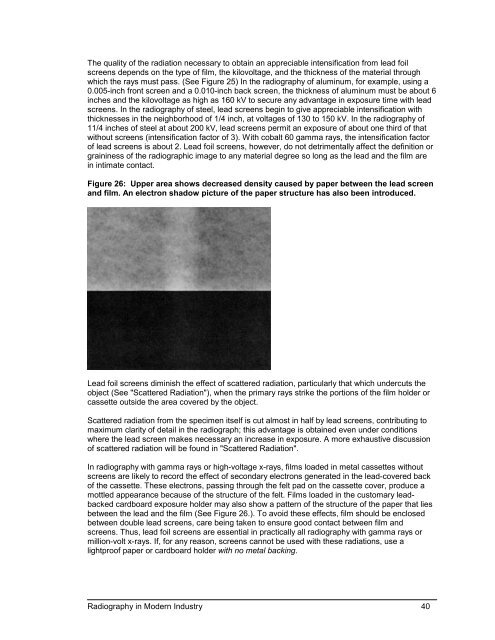

The quality of the radiation necessary to obta<strong>in</strong> an appreciable <strong>in</strong>tensification from lead foilscreens depends on the type of film, the kilovoltage, and the thickness of the material throughwhich the rays must pass. (See Figure 25) In the radiography of alum<strong>in</strong>um, for example, us<strong>in</strong>g a0.005-<strong>in</strong>ch front screen and a 0.010-<strong>in</strong>ch back screen, the thickness of alum<strong>in</strong>um must be about 6<strong>in</strong>ches and the kilovoltage as high as 160 kV to secure any advantage <strong>in</strong> exposure time with leadscreens. In the radiography of steel, lead screens beg<strong>in</strong> to give appreciable <strong>in</strong>tensification withthicknesses <strong>in</strong> the neighborhood of 1/4 <strong>in</strong>ch, at voltages of 130 to 150 kV. In the radiography of11/4 <strong>in</strong>ches of steel at about 200 kV, lead screens permit an exposure of about one third of thatwithout screens (<strong>in</strong>tensification factor of 3). With cobalt 60 gamma rays, the <strong>in</strong>tensification factorof lead screens is about 2. Lead foil screens, however, do not detrimentally affect the def<strong>in</strong>ition orgra<strong>in</strong><strong>in</strong>ess of the radiographic image to any material degree so long as the lead and the film are<strong>in</strong> <strong>in</strong>timate contact.Figure 26: Upper area shows decreased density caused by paper between the lead screenand film. An electron shadow picture of the paper structure has also been <strong>in</strong>troduced.Lead foil screens dim<strong>in</strong>ish the effect of scattered radiation, particularly that which undercuts theobject (See "Scattered Radiation"), when the primary rays strike the portions of the film holder orcassette outside the area covered by the object.Scattered radiation from the specimen itself is cut almost <strong>in</strong> half by lead screens, contribut<strong>in</strong>g tomaximum clarity of detail <strong>in</strong> the radiograph; this advantage is obta<strong>in</strong>ed even under conditionswhere the lead screen makes necessary an <strong>in</strong>crease <strong>in</strong> exposure. A more exhaustive discussionof scattered radiation will be found <strong>in</strong> "Scattered Radiation".In radiography with gamma rays or high-voltage x-rays, films loaded <strong>in</strong> metal cassettes withoutscreens are likely to record the effect of secondary electrons generated <strong>in</strong> the lead-covered backof the cassette. These electrons, pass<strong>in</strong>g through the felt pad on the cassette cover, produce amottled appearance because of the structure of the felt. Films loaded <strong>in</strong> the customary leadbackedcardboard exposure holder may also show a pattern of the structure of the paper that liesbetween the lead and the film (See Figure 26.). To avoid these effects, film should be enclosedbetween double lead screens, care be<strong>in</strong>g taken to ensure good contact between film andscreens. Thus, lead foil screens are essential <strong>in</strong> practically all radiography with gamma rays ormillion-volt x-rays. If, for any reason, screens cannot be used with these radiations, use alightproof paper or cardboard holder with no metal back<strong>in</strong>g.<strong>Radiography</strong> <strong>in</strong> <strong>Modern</strong> <strong>Industry</strong> 40