- Page 1 and 2: RadiographyinModernIndustry

- Page 3 and 4: RadiographyinModernIndustryFOURTH E

- Page 5 and 6: ContentsIntroduction...............

- Page 7 and 8: Chapter 1: The Radiographic Process

- Page 9 and 10: Intensifying ScreensX-ray and other

- Page 11 and 12: makes it a very suitable material f

- Page 13 and 14: Figure 6: Typical voltage waveforms

- Page 15 and 16: Table I - Typical X-ray Machines an

- Page 17 and 18: The wavelengths (or energies of rad

- Page 19 and 20: Table III - Industrial Gamma-Ray So

- Page 21 and 22: 1. The source of light should be sm

- Page 23 and 24: B and H in the Figure 13 show the e

- Page 25 and 26: Figure 14: Geometric construction f

- Page 27 and 28: Figure 17: Pinhole pictures of the

- Page 29 and 30: The kilovoltage applied to the x-ra

- Page 31 and 32: Figure 21: Schematic diagram of som

- Page 33 and 34: kind of material radiographed, the

- Page 35 and 36: instance, the kilovoltage may be fi

- Page 37 and 38: The technique need not be limited t

- Page 39 and 40: Chapter 5: Radiographic ScreensWhen

- Page 41 and 42: Contact between the film and the le

- Page 43 and 44: Figure 29: The number of electrons

- Page 45 and 46: lead foil screens ran be retained w

- Page 47 and 48: Figure 33: The sharpness of the rad

- Page 49: Figure 34: Low density (right) is a

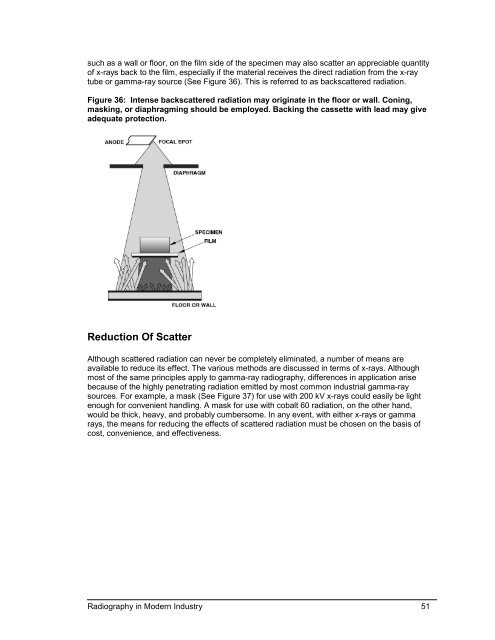

- Page 53 and 54: from this source. Since scatter als

- Page 55 and 56: A filter reduces excessive subject

- Page 57 and 58: Definite rules as to filter thickne

- Page 59 and 60: 0.010-inch front screen of value be

- Page 61 and 62: Example: Suppose that with a given

- Page 63 and 64: If the milliamperage remains consta

- Page 65 and 66: espectively. In other words, a cons

- Page 67 and 68: Any given exposure chart applies to

- Page 69 and 70: Figure 46: Typical gamma-ray exposu

- Page 71 and 72: where the slope of the characterist

- Page 73 and 74: Figure 49: Characteristic curves of

- Page 75 and 76: Figure 51: Characteristic curve of

- Page 77 and 78: Nomogram MethodsIn Figure 54, the s

- Page 79 and 80: Figure 56: Transparent overlay posi

- Page 81 and 82: Figure 58: Overlay positioned so as

- Page 83 and 84: The problem of radiographing a part

- Page 85 and 86: Figure 62: System of lines drawn on

- Page 87 and 88: Chapter 8: Radiographic Image Quali

- Page 89 and 90: Film contrast refers to the slope (

- Page 91 and 92: Hole Type PenetrametersThe common p

- Page 93 and 94: of the same thickness as the specim

- Page 95 and 96: Chapter 9: Industrial X-ray FilmsMo

- Page 97 and 98: Figure 70 indicates the direction t

- Page 99 and 100: the lead letters on a radiation-abs

- Page 101 and 102:

Therefore, protection requirements

- Page 103 and 104:

5. Avoid pressure damage caused by

- Page 105 and 106:

Paddles or plunger-type agitators a

- Page 107 and 108:

slow, and the development time reco

- Page 109 and 110:

ubbles make their way to the surfac

- Page 111 and 112:

When development is complete, the f

- Page 113 and 114:

soften considerably with prolonged

- Page 115 and 116:

Figure 77: The roller transport sys

- Page 117 and 118:

Rapid Access to Processed Radiograp

- Page 119 and 120:

Figure 78: Film-feeding procedures

- Page 121 and 122:

Chapter 11: Process ControlUsers of

- Page 123 and 124:

3. Age of the developer replenisher

- Page 125 and 126:

Figure 80: Control chart below for

- Page 127 and 128:

DiscussionDensitometric data and pr

- Page 129 and 130:

Figure 82: Plan of a manual x-ray p

- Page 131 and 132:

Figure 83: A schematic diagram of a

- Page 133 and 134:

loading-bench activities are carrie

- Page 135 and 136:

KODAK Quinone-Thiosulfate Intensifi

- Page 137 and 138:

Methylene-Blue MethodTwo variations

- Page 139 and 140:

KODAK Hypo Test Solution HT-2Avoird

- Page 141 and 142:

In summary, use of the test papers

- Page 143 and 144:

narrow angle would be very thick, e

- Page 145 and 146:

When radiation passes through a spe

- Page 147 and 148:

Figure 89: Demonstration of the eff

- Page 149 and 150:

Figure 90: The amount of gamma radi

- Page 151 and 152:

The radiograph exposed in the right

- Page 153 and 154:

To illustrate, let us assume that t

- Page 155 and 156:

Figure 95: High-speed x-ray picture

- Page 157 and 158:

Figure 97: Two methods of neutron r

- Page 159 and 160:

Duplicating RadiographsSimultaneous

- Page 161 and 162:

Sometimes, as when sets of referenc

- Page 163 and 164:

PhotofluorographyIn photofluorograp

- Page 165 and 166:

discontinuities or of segregation i

- Page 167 and 168:

from the camera or by reaching down

- Page 169 and 170:

Figure 106: Schematic diagram of th

- Page 171 and 172:

valuable technique, for instance, i

- Page 173 and 174:

The position of the spots is determ

- Page 175 and 176:

Powder Diffraction File, Internatio

- Page 177 and 178:

Processing TechniquesRadiographs on

- Page 179 and 180:

Since this formula applies only to

- Page 181 and 182:

such that it does not distort the i

- Page 183 and 184:

Figure 113: A: Representation of a

- Page 185 and 186:

Figure 115: Characteristic curve of

- Page 187 and 188:

film fairly well. If high densities

- Page 189 and 190:

Density = 1.5 Density = 2.5Film Rel

- Page 191 and 192:

In most industrial radiography, the

- Page 193 and 194:

e noted here. Although the average

- Page 195 and 196:

Chapter 17: Film Graininess; Signal

- Page 197 and 198:

The ratio of signal to noise has a

- Page 199 and 200:

Chapter 18: The Photographic Latent

- Page 201 and 202:

Thus, the change that makes an expo

- Page 203 and 204:

Figure 130: Stages in the developme

- Page 205 and 206:

electrons by successive Compton int

- Page 207 and 208:

Development is essentially a chemic

- Page 209 and 210:

Chapter 19: ProtectionOne of the mo

- Page 211 and 212:

duct is brought into the x-ray room