Radiography in Modern Industry - Kodak

Radiography in Modern Industry - Kodak

Radiography in Modern Industry - Kodak

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

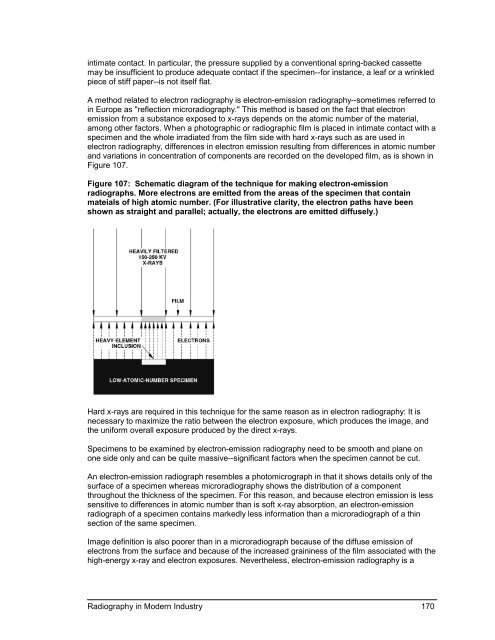

<strong>in</strong>timate contact. In particular, the pressure supplied by a conventional spr<strong>in</strong>g-backed cassettemay be <strong>in</strong>sufficient to produce adequate contact if the specimen--for <strong>in</strong>stance, a leaf or a wr<strong>in</strong>kledpiece of stiff paper--is not itself flat.A method related to electron radiography is electron-emission radiography--sometimes referred to<strong>in</strong> Europe as "reflection microradiography." This method is based on the fact that electronemission from a substance exposed to x-rays depends on the atomic number of the material,among other factors. When a photographic or radiographic film is placed <strong>in</strong> <strong>in</strong>timate contact with aspecimen and the whole irradiated from the film side with hard x-rays such as are used <strong>in</strong>electron radiography, differences <strong>in</strong> electron emission result<strong>in</strong>g from differences <strong>in</strong> atomic numberand variations <strong>in</strong> concentration of components are recorded on the developed film, as is shown <strong>in</strong>Figure 107.Figure 107: Schematic diagram of the technique for mak<strong>in</strong>g electron-emissionradiographs. More electrons are emitted from the areas of the specimen that conta<strong>in</strong>mateials of high atomic number. (For illustrative clarity, the electron paths have beenshown as straight and parallel; actually, the electrons are emitted diffusely.)Hard x-rays are required <strong>in</strong> this technique for the same reason as <strong>in</strong> electron radiography: It isnecessary to maximize the ratio between the electron exposure, which produces the image, andthe uniform overall exposure produced by the direct x-rays.Specimens to be exam<strong>in</strong>ed by electron-emission radiography need to be smooth and plane onone side only and can be quite massive--significant factors when the specimen cannot be cut.An electron-emission radiograph resembles a photomicrograph <strong>in</strong> that it shows details only of thesurface of a specimen whereas microradiography shows the distribution of a componentthroughout the thickness of the specimen. For this reason, and because electron emission is lesssensitive to differences <strong>in</strong> atomic number than is soft x-ray absorption, an electron-emissionradiograph of a specimen conta<strong>in</strong>s markedly less <strong>in</strong>formation than a microradiograph of a th<strong>in</strong>section of the same specimen.Image def<strong>in</strong>ition is also poorer than <strong>in</strong> a microradiograph because of the diffuse emission ofelectrons from the surface and because of the <strong>in</strong>creased gra<strong>in</strong><strong>in</strong>ess of the film associated with thehigh-energy x-ray and electron exposures. Nevertheless, electron-emission radiography is a<strong>Radiography</strong> <strong>in</strong> <strong>Modern</strong> <strong>Industry</strong> 170