Manual optoNCDT 1402 - Micro-Epsilon

Manual optoNCDT 1402 - Micro-Epsilon

Manual optoNCDT 1402 - Micro-Epsilon

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

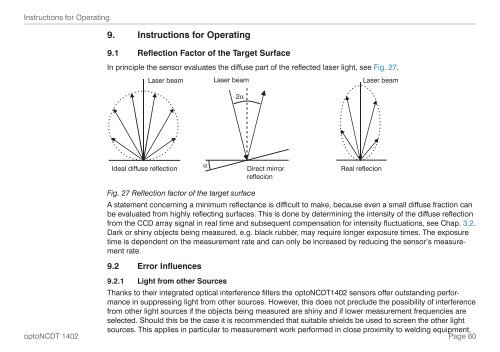

Instructions for Operating9. Instructions for Operating9.1 Reflection Factor of the Target SurfaceIn principle the sensor evaluates the diffuse part of the reflected laser light, see Fig. 27.Laser beam Laser beamLaser beam2Ideal diffuse reflectionDirect mirrorreflecionReal reflecion<strong>optoNCDT</strong> <strong>1402</strong>Fig. 27 Reflection factor of the target surfaceA statement concerning a minimum reflectance is difficult to make, because even a small diffuse fraction canbe evaluated from highly reflecting surfaces. This is done by determining the intensity of the diffuse reflectionfrom the CCD array signal in real time and subsequent compensation for intensity fluctuations, see Chap. 3.2.Dark or shiny objects being measured, e.g. black rubber, may require longer exposure times. The exposuretime is dependent on the measurement rate and can only be increased by reducing the sensor’s measurementrate.9.2 Error Influences9.2.1 Light from other SourcesThanks to their integrated optical interference filters the <strong>optoNCDT</strong><strong>1402</strong> sensors offer outstanding performancein suppressing light from other sources. However, this does not preclude the possibility of interferencefrom other light sources if the objects being measured are shiny and if lower measurement frequencies areselected. Should this be the case it is recommended that suitable shields be used to screen the other lightsources. This applies in particular to measurement work performed in close proximity to welding equipment.Page 80