- Page 1:

REPAIR MANUALSELF-PROPELLED TELESCO

- Page 4 and 5:

21 Repair manual

- Page 6 and 7:

Repair Manual2.2.1 - H14T(X) size .

- Page 8 and 9:

Repair Manual5.18.4 - Indicator def

- Page 10 and 11:

6Repair Manual

- Page 12 and 13:

Repair manual1.2 - GENERAL SAFETY I

- Page 14 and 15:

Repair manual1.3 - RESIDUAL RISKSCa

- Page 16 and 17:

1.5 - REPAIRS AND ADJUSTMENTS1.6 -

- Page 18 and 19:

Repair manualDESCRIPTION H14T(X) Un

- Page 20 and 21:

Repair manual2.2 - SIZE2.2.1 - H14T

- Page 22 and 23:

Repair manual2.3 - TIGHTENING TORQU

- Page 24 and 25:

20Repair manual

- Page 26 and 27:

Repair manual3.1.4 - Safety inputsS

- Page 28 and 29:

24Repair manual

- Page 30 and 31:

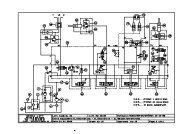

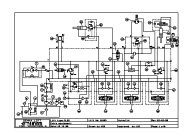

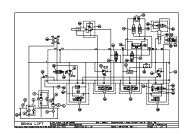

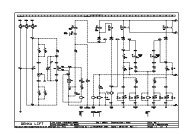

Repair manual4.2 - DIAGRAM E 523 -

- Page 32 and 33:

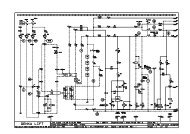

Repair manual4.4 - DIAGRAM E 523 -

- Page 34 and 35:

30Repair manual

- Page 36 and 37:

135 Repair manual5.6 - JIB5.6.1 - U

- Page 38 and 39:

135 Repair manual5.10.2 -Platform5.

- Page 40 and 41:

135 Repair manual5.18 - OTHER FUNCT

- Page 42 and 43:

135 Repair manual6.1.2 - Positions

- Page 44 and 45:

135 Repair manual6.1.4 - Positions

- Page 46 and 47:

Repair manual7.2 - DIAGRAM H16TP(X)

- Page 48 and 49:

Repair manualTo preserve the integr

- Page 50 and 51:

Repair manual8.5 - MAINTENANCE PLAN

- Page 52 and 53:

Repair manual8.6 - OPERATIONS8.6.1

- Page 54 and 55:

Repair manualRef Code Qty Descripti

- Page 56 and 57:

Repair manual8.7.3 - Common "yellow

- Page 58 and 59:

Repair manual8.7.5 - Labels specifi

- Page 60 and 61:

Repair manual24 2356

- Page 62 and 63:

58Repair manual

- Page 64 and 65:

60135 Repair manual

- Page 67 and 68:

PREVENTIVE MAINTENANCE SHEETSheet P

- Page 69 and 70:

PREVENTIVE MAINTENANCE SHEETSheet P

- Page 71 and 72:

Repair manual10 - OPERATING INCIDEN

- Page 73 and 74:

Repair manualNo movement available

- Page 75 and 76:

Repair manual10.1.3 -Travel systemA

- Page 77 and 78:

Sheet DP015BREAKDOWN DETECTION FLOW

- Page 79 and 80:

Sheet DP016BREAKDOWN DETECTION FLOW

- Page 81:

Sheet DP016BREAKDOWN DETECTION FLOW

- Page 84 and 85:

Sheet DP018BREAKDOWN DETECTION FLOW

- Page 87 and 88:

Sheet DP019BREAKDOWN DETECTION FLOW

- Page 89:

Sheet DP020BREAKDOWN DETECTION FLOW

- Page 93 and 94:

Sheet DP022BREAKDOWN DETECTION FLOW

- Page 95 and 96:

Sheet DP023BREAKDOWN DETECTION FLOW

- Page 97 and 98:

Sheet DP023BREAKDOWN DETECTION FLOW

- Page 99:

Sheet DP023BREAKDOWN DETECTION FLOW

- Page 102 and 103:

Sheet DP024BREAKDOWN DETECTION FLOW

- Page 104 and 105:

Sheet DP025BREAKDOWN DETECTION FLOW

- Page 106 and 107:

Sheet DP026BREAKDOWN DETECTION FLOW

- Page 108 and 109:

Sheet DP026BREAKDOWN DETECTION FLOW

- Page 111 and 112:

Sheet DP027BREAKDOWN DETECTION FLOW

- Page 113 and 114:

Sheet DP027BREAKDOWN DETECTION FLOW

- Page 115:

Sheet DP027BREAKDOWN DETECTION FLOW

- Page 118 and 119:

Sheet DP028BREAKDOWN DETECTION FLOW

- Page 120 and 121:

Sheet DP028BREAKDOWN DETECTION FLOW

- Page 123 and 124:

Sheet DP030BREAKDOWN DETECTION FLOW

- Page 125:

Sheet DP030BREAKDOWN DETECTION FLOW

- Page 128 and 129:

Sheet DP032BREAKDOWN DETECTION FLOW

- Page 130 and 131:

Sheet DP032BREAKDOWN DETECTION FLOW

- Page 132 and 133:

Sheet DP034BREAKDOWN DETECTION FLOW

- Page 134 and 135:

Sheet DP034BREAKDOWN DETECTION FLOW

- Page 136 and 137: Sheet DP036BREAKDOWN DETECTION FLOW

- Page 139: Sheet DP041BREAKDOWN DETECTION FLOW

- Page 142 and 143: Sheet DP056BREAKDOWN DETECTION FLOW

- Page 145 and 146: Sheet DP060BREAKDOWN DETECTION FLOW

- Page 147 and 148: Sheet DP060BREAKDOWN DETECTION FLOW

- Page 149 and 150: Sheet DP072BREAKDOWN DETECTION FLOW

- Page 151 and 152: Sheet DP072BREAKDOWN DETECTION FLOW

- Page 153 and 154: Repair manual11 - CORRECTIVE MAINTE

- Page 155: Sheet C010CORRECTIVE MAINTENANCE SH

- Page 159 and 160: Sheet C035CORRECTIVE MAINTENANCE SH

- Page 161: Sheet C038CORRECTIVE MAINTENANCE SH

- Page 165: CORRECTIVE MAINTENANCE SHEETSheet C

- Page 169 and 170: Sheet C042CORRECTIVE MAINTENANCE SH

- Page 171: Sheet C043CORRECTIVE MAINTENANCE SH

- Page 175: Sheet C045CORRECTIVE MAINTENANCE SH

- Page 179: CORRECTIVE MAINTENANCE SHEETSheet C

- Page 183: Sheet C051CORRECTIVE MAINTENANCE SH

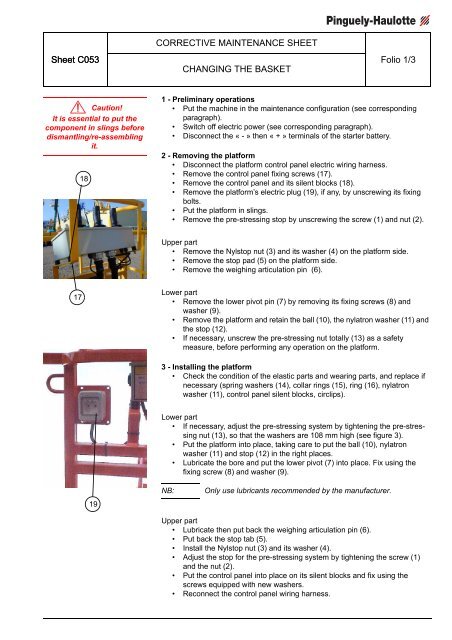

- Page 188 and 189: Sheet C053CORRECTIVE MAINTENANCE SH

- Page 191: CORRECTIVE MAINTENANCE SHEETSheet C

- Page 194 and 195: Sheet C055CORRECTIVE MAINTENANCE SH

- Page 196 and 197: CORRECTIVE MAINTENANCE SHEET

- Page 199: Sheet C059CORRECTIVE MAINTENANCE SH

- Page 202 and 203: CORRECTIVE MAINTENANCE SHEETSheet C

- Page 205: Sheet C064CORRECTIVE MAINTENANCE SH

- Page 208 and 209: CORRECTIVE MAINTENANCE SHEET

- Page 211: CORRECTIVE MAINTENANCE SHEETSheet C

- Page 214 and 215: Sheet C069CORRECTIVE MAINTENANCE SH

- Page 216 and 217: Sheet C073CORRECTIVE MAINTENANCE SH

- Page 218 and 219: Sheet C073CORRECTIVE MAINTENANCE SH

- Page 220 and 221: Sheet C074CORRECTIVE MAINTENANCE SH

- Page 222 and 223: Sheet C075CORRECTIVE MAINTENANCE SH

- Page 225 and 226: CORRECTIVE MAINTENANCE SHEETSheet C

- Page 227: Sheet C079CORRECTIVE MAINTENANCE SH

- Page 231: Sheet C082CORRECTIVE MAINTENANCE SH

- Page 235 and 236: Sheet C120CORRECTIVE MAINTENANCE SH

- Page 237 and 238:

Sheet C121CORRECTIVE MAINTENANCE SH

- Page 239 and 240:

Sheet C121CORRECTIVE MAINTENANCE SH

- Page 241 and 242:

CORRECTIVE MAINTENANCE SHEETSheet C

- Page 243:

CORRECTIVE MAINTENANCE SHEETSheet C

- Page 247:

CORRECTIVE MAINTENANCE SHEETSheet C

- Page 250 and 251:

Sheet C126CORRECTIVE MAINTENANCE SH

- Page 253 and 254:

Sheet C128CORRECTIVE MAINTENANCE SH

- Page 255 and 256:

Sheet C128CORRECTIVE MAINTENANCE SH

- Page 257 and 258:

Sheet C128CORRECTIVE MAINTENANCE SH

- Page 259 and 260:

Sheet C129CORRECTIVE MAINTENANCE SH

- Page 261 and 262:

Sheet C129CORRECTIVE MAINTENANCE SH

- Page 263 and 264:

Sheet C129CORRECTIVE MAINTENANCE SH

- Page 265 and 266:

Sheet C130CORRECTIVE MAINTENANCE SH

- Page 267 and 268:

Sheet C131CORRECTIVE MAINTENANCE SH

- Page 269 and 270:

Sheet C136CORRECTIVE MAINTENANCE SH

- Page 271 and 272:

Sheet C138CORRECTIVE MAINTENANCE SH